Engine Tune-Up

VARIABLE SPEED MECHANICAL GOVERNOR AND INJECTOR RACK

CONTROL ADJUSTMENT

6, 8 and 12V ENGINES

tube assemblies which have a yield spring at each

The single - weight variable speed governor is mounted

injector rack control lever and only one screw and lock

on the front of the engine and is driven by the blower

nut to keep each injector rack properly positioned.

rotor.

Adjust the single screw and lock nut on each injector

rack control lever the same as for the two screw rack

After adjusting the exhaust valves and timing the fuel

control lever.

injectors, a d j u s t the variable speed mechanical

governor and injector rack control levers.

Properly positioned injector rack control levers, with

NOTE: Before proceeding with the governor and

the engine at full load, will result in the following:

i n j e c t o r rack adjustments. disconnect any

supplementary governing device. After the

1. Speed control lever at the maximum speed position.

adjustments a r e completed, reconnect and

adjust the supplementary governing device.

2. Stop lever in the Run position.

3 . High speed spring plunger is within .005" to

Adjust Governor Gap

.007" of its seat in the governor control housing.

With the engine stopped and at normal operating

4. Injector fuel control racks in the full fuel position.

temperature, adjust the governor gap as follows:

1. Disconnect any linkage attached to the governor

The letters R and L indicate the injector location in

levers.

the right or left cylinder bank, viewed from the rear of

the engine. The cylinders are numbered starting at the

2. Back out the buffer screw until

it

extends

front of the engine on each cylinder hank. Adjust the

approximately 5/8" from the lock nut.

3. Clean and remove the governor cover and valve

rocker covers. Discard the gaskets.

4. Place the speed control lever in the maximum speed

position.

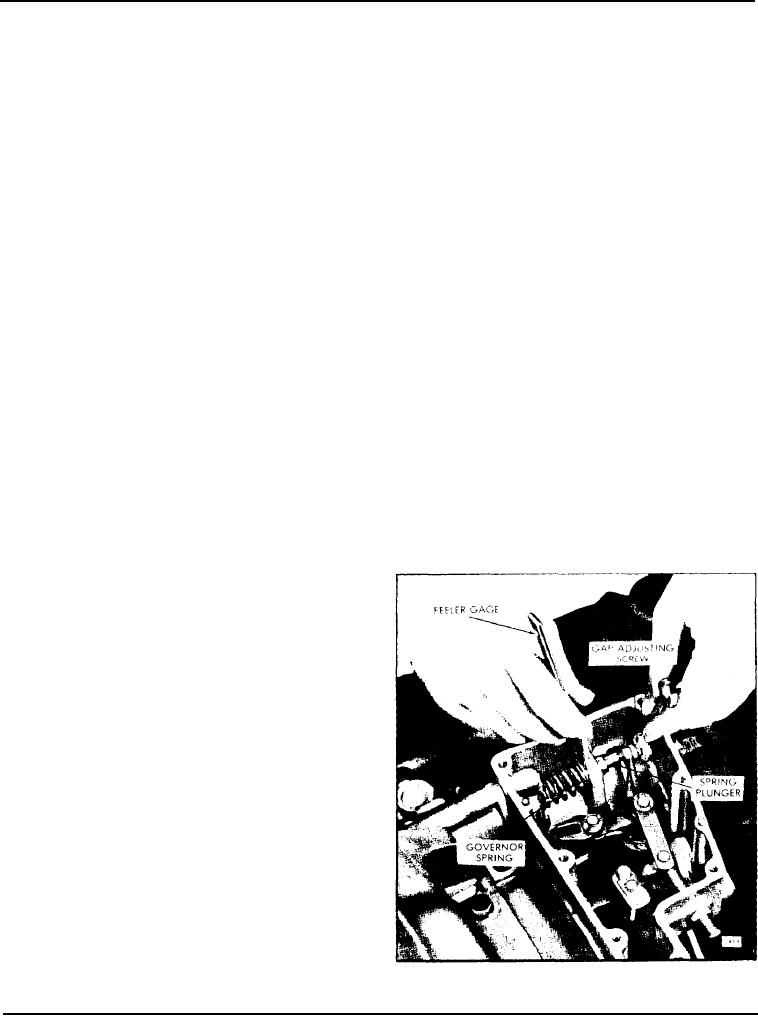

5. Insert a .006" feeler gage between the spring

plunger and the plunger guide as shown in Fig. 1. If

required, loosen the lock nut and turn the adjusting

screw until a slight drag is noted on the feeler gage.

6. Hold the adjusting screw and tighten the lock nut.

Check the gap again and, if necessary, readjust.

7. Use a new gasket and install the governor cover.

Tighten the screws.

Position Injector Rock Control levers

The position

of the injector control rack levers must be

correctly set

in relation to the governor. Their position

determines

the amount of fuel injected into each

cylinder and

ensures equal distribution of the load.

Fig. 1 - Adjusting Governor Gap

Certain engines use spring-loaded injector control

Page 107