Engine Tune-Up

control lever while positioning the No. 2L injector

CAUTION: Care should be taken to avoid

rack. If the rack of the No. 1L injector has become

setting the racks too tight and causing the fuel

loose, back off the inner adjusting screw slightly on the

rod to bend.

No. 2L injector rack control lever. Tighten the outer

7 . To be sure the rack control lever is properly

adjusting screw. When the settings are correct, both

adjusted, press down on the injector rack with a screw

injector racks must respond in the same manner on the

driver or finger tip (Fig. 3). A. light pressure should

hall end of their respective rack control levers as

cause the rack to rotate. The rack is sufficiently tight if

previously outlined in Step 7.

the rack returns or springs back to its original position

when the pressure is removed. The rack is too tight if

12. Position the remaining injector rack control levers

a heavy pressure is required to rotate the rack.

on the left and right cylinder heads as outlined in

Steps 10 and 11 When the settings are correct, all of

8. Adjust the No. 1L injector rack control lever as

the injector racks will be snug on the ball end of the

outlined in Steps 6 and 7.

control levers when the injector control tube lever is

held in the full-fuel position.

9. Check the adjustment on the 1R and 1L injector

rack control levers. If the setting is correct, the injector

13. Remove the bolt from the recessed hole in the

racks will be in the full-fuel position and snug on the

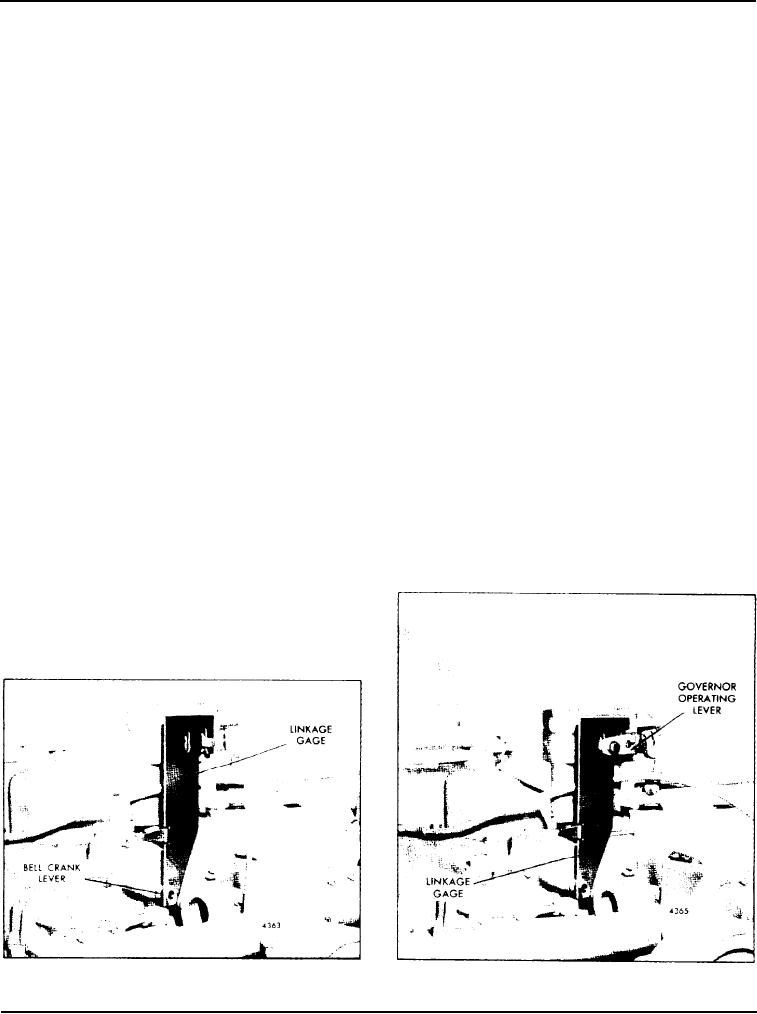

drive housing a n d install linkage gage J 21304

ball end of the control levers.

(Fig. 4).

10. To adjust the remaining injector rack control

14. Replace the governor operating lever on the

levers, hold the No. IL injector rack in the full-fuel

serrated shaft so that the bolt hole is lined up within

position by means of the lever on the end of the

the proper lines on the gage (Fig. 5). The type of

control tube assembly. Turn down the inner adjusting

governor (SGX or PSG) will determine the proper

screw of the No. 2L injector rack control lever until

position of the lever.

the injector rack has moved into the full--fuel position.

Turn the outer adjusting screw down until it bottoms

15. Remove the gage.

lightly on the injector control tube. Then alternately

tighten both the inner and outer adjusting screws.

16. Move the bell crank lever to the no-fuel position.

NOTE: Overtightening of the injector rack

17. Adjust the length of the vertical link so that the

control lever adjusting screws during installa-

bolt holes of the levers and the centers of the rod end

tion or adjustment can result in damage to the

bearings are lined up (Fig. 6).

injector control tube. The recommended torque

of the adjusting screws is 24-36 in-lbs (3-4

Nm).

11. Recheck the No. 1L injector rack to be sure that it

has remained snug on the ball end of-the injector rack

Fig. 5 - Governor Operating Lever in Position

Fig. 4 - Linkage Gage in Position

Page 122