Engine Tune-Up

THROTTLE DELAY MECHANISM

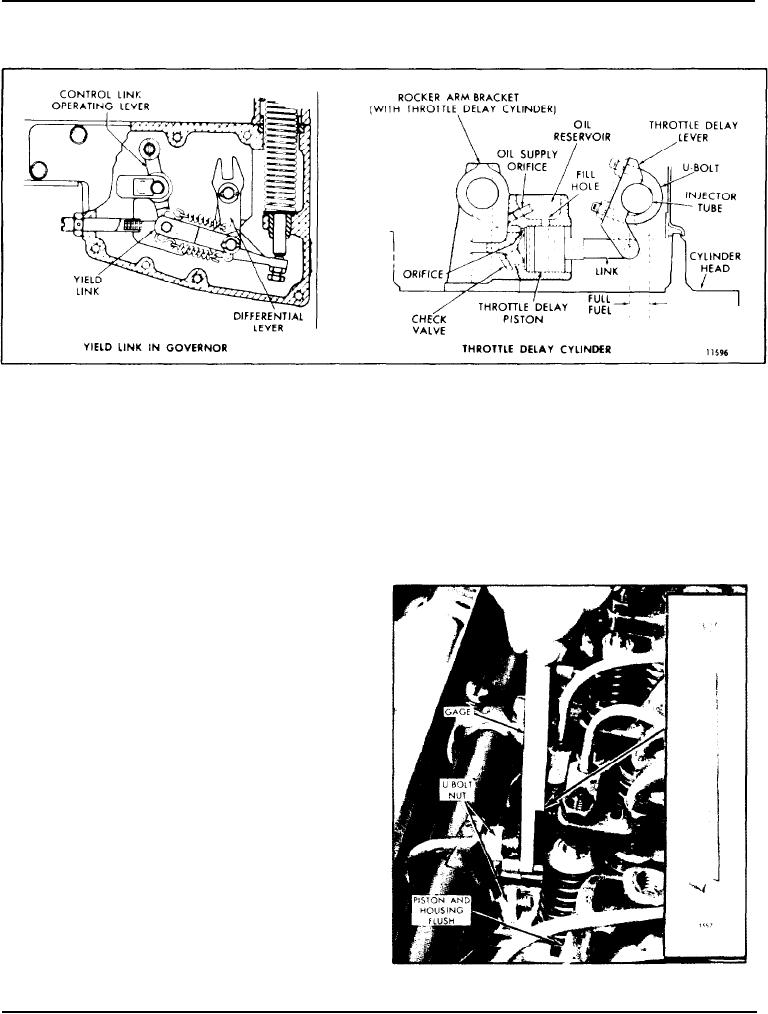

Fig. 3 - Throttle Delay Cylinder and Yield Link

The throttle delay mechanism is used to retard full

Inspection

fuel injection when the engine is accelerated. This

When inspecting the throttle delav hydraulic cylinder

reduces exhaust smoke and also helps to improve fuel

it is important that the check valve be inspected for

economy.

wear. Replace the check valve if necessary.

The throttle delay mechanism (Fig. 3) is installed

To inspect the check valve, fill the throttle delay

between the No. 1 and No. 2 cylinders on the right-

cylinder with diesel fuel oil and watch for check valve

hank cylinder head. It consists of a special rocker arm

leakage while moving the engine throttle from the idle

shaft bracket (which incorporates the throttle delay

position to the full fuel position

cylinder), a piston, throttle delay lever, connecting

link, orifice plug. hall check valve and U-bolt.

A yield link replaces the standard operating lever

connecting link in the governor.

Operation

Oil is supplied to a reservoir above the throttle delay

cylinder through an orifice plug in the drilled oil

passage in the rocker arm shaft bracket (Fig. 3). As

the injector racks are moved toward the no-fuel

position, free movement of the throttle delay piston is

assured by air drawn into the cylinder through the ball

check valve. Further movement of the piston uncovers

an opening which permits oil from the reservoir to

enter the cylinder and displace the air. When the

engine is accelerated, movement of the injector racks

toward the full-fuel position is momentarily) retarded

while the piston expels the oil from the cylinder

through an orifice. To permit full accelerator travel,

regardless of the retarded injector rack position, a

spring loaded yield link replaces the standard

operating lever connecting link in the governor.

Fig. 4 - Adjusting Throttle Delay Cylinder

Page 119