Engine Tune-Up

HYDRAULIC OUTPUT SHAFT GOVERNOR AND LINKAGE ADJUSTMENT

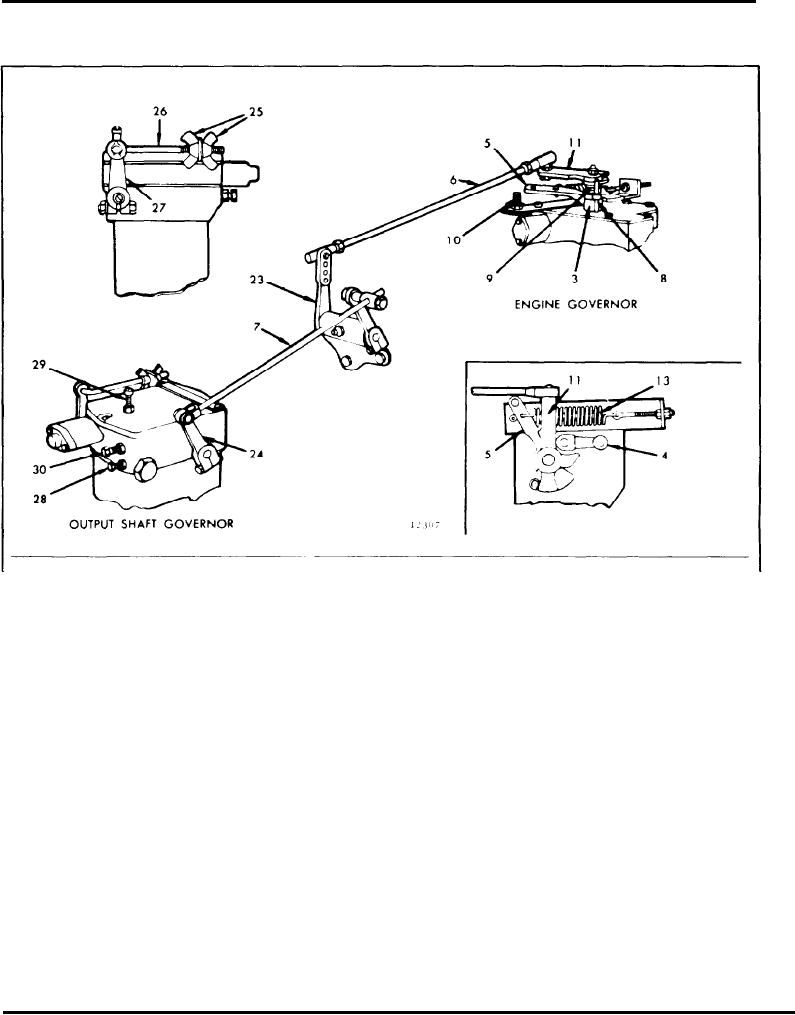

3. Lever--Throttle Control

8.

Pin--Stop

23 Lever--Throttle Control

27 Lever--Speed Control

4. Lever--Shutdown

9

Spring--Torsion

Rear Cross Shaft

28. Screw--Maximum Speed

5. Lever--Engine Governor

10

Bolt (Stop)

24. Lever--Output Shaft

Limit Adjusting

11

Lever--Output Shaft

29. Screw--Minimum Speed

Governor Control

Operating

Governor

Limit Adjusting

6. Rod--Engine Governor

25. Wing Nut--Speed

7. Rod--Output Shaft

13. Spring--Governor Lever

Adjusting

30. Screw--Maximum Fuel

Governor

Return

26 Link--Sliding

Adjusting

Fig. 1 - Hydraulic Output Shaft Governor and Linkage

A hydraulic governor is used to maintain a near

constant output shaft speed. The output shaft speed

constant output shaft speed on engines equipped with

will be constant up to full power of the engine, except

a Series 500 or larger Torqmatic converter. The

for the amount of governor droop. The speed setting

governor is mounted on the converter and gear driven

of the engine governor must be sufficiently higher than

from the output shaft.

the speed setting of the output shaft governor so the

engine governor will not reduce the fuel input to the

engine before full power is required by the output

The output shaft governor is connected to the engine

shaft governor. As load is applied to the output shaft,

governor by control rods and levers (Fig. 1). The

the output shaft speed will decrease gradually up to

control rod end ball joints are sealed assemblies and

the amount of the output shaft governor droop at full

do not require lubrication. Other moving parts of the

load. At the same time, the engine speed will gradually

control linkage should be lubricated with engine oil.

increase until full load is reached.

In most applications, such as drag line and shovel

operation, it is desirable to have the output shaft

In some types of operation, such as laying of structural

steel, it is desirable to operate the unit with a very low

governor control the fuel input to maintain a relatively

Page 148