Engine Tune-Up

Not more than one unit in a system of paralleled

alternators with engines controlled by centrifugal

governors can be operated on "zero" droop.

If necessary, adjust the speed droop as follows:

1. Start the engine and run it at approximately half-

load until the lubricating oil temperature is stabilized;

governor regulation will become more stable as the oil

temperature increases.

2. Stop the engine and remove the actuator cover.

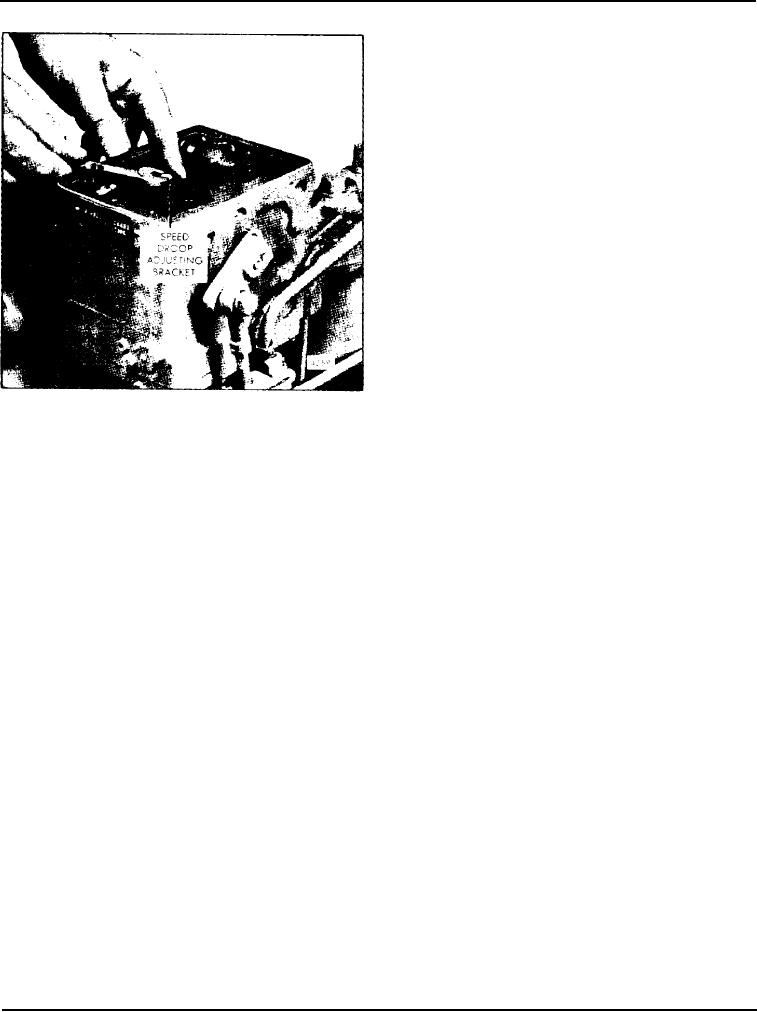

3. Loosen the speed droop adjusting bracket screw and

move the bracket (Fig. 7) slightly to obtain the desired

droop; moving the bracket toward the flyweight end of

the actuator will increase the droop. Tighten the screw.

4. Install the actuator cover and, with the engine

running, adjust the speed until the engine is operating

at the desired speed above the rated full-load speed.

5. Apply the full rated load on the engine and readjust

the speed to the correct full-load speed.

Fig. 7 - Adjusting Speed Droop

6. Remove the rated load and note the engine speed

after it stabilizes under no load. If necessary, stop the

droop adjustment has no effect on operation and

engine, remove the actuator cover and readjust the

should be left as factory set. When, for some reason,

speed droop bracket.

the centrifugal governor section is controlling the

engine, the speed droop setting can be adjusted, if

After the engine tune -up is completed, reconnect the

necessary, to suit the operating requirements. The

electrical circuit of the governor at the receptacle on

governor should never be set at "zero" droop unless

the actuator cover. If necessary, refer to the

the unit is maintaining the frequency of paralleled

Woodward Governor Company's Bulletin 37709 for

alternators or is operating as a single, isolated unit.

the procedures to be followed in checking the electrical

system.

16V ENGINE

The tune-up procedure for a 16V engine equipped

the variable speed hydraulic governor (6. 8 and 12V)

with the EG-B electric governor is similar to the

or in the variable speed hydraulic governor (16V). The

procedure used on the 6, 8 or 12V engines. To position

governor adjustments, however, are the same as on the

the injector rack control levers, use the same linkage

6, 8 and 12V engines.

gage (J 22195) but follow the procedure outlined in

Page 144