SPECIFICATIONS AND SERVICE DATA-POWER SHIFT TRANSMISSION

AND TORQUE CONVERTER

CLUTCH PRESSURE

CONVERTER OUT

180-220 psi. [12,7-15, 4kg/cm]-With parking

55 min. - 70 max. psi. [3,9- 4,9 kg/cm']

Transmission in neutral.

PRESSURE

brake set (see note), oil temperature 180-200 F.

oil Temperature 180-200 F [82,2-93,3 C.]

[82,2-93,3 C], engine at idle (400 to 600 RPM),

Engine at 2000 RPM.

shift thru direction and speed clutches. All clutch

pressure must be equal within 5 psi. [0,4 kg/m].

Forward and Reverse - Manual

CONTROLS

If clutch pressure varies in any one clutch more.

Speed Selection - Manual

than 5 psi [0.4 kg/cm] repair clutch.

CLUTCH TYPE

Multiple discs, hydraulically actuated, spring

released, automatic wear compensation and no

adjustment.

All clutches oil cooled and lubri-

cated.

CLUTCH INNER DISC Friction

CLUTCH OUTER DISC Steel

OIL FILTRATION

Full flow oil filter safety by-pars, also strainer

ALWAYS USE PARKING BRAKE WHEN MAKING

screen in sump at bottom of transmission case.

CLUTCH PRESSURE CHECKS.

LUBRICATION

TYPE OF OIL

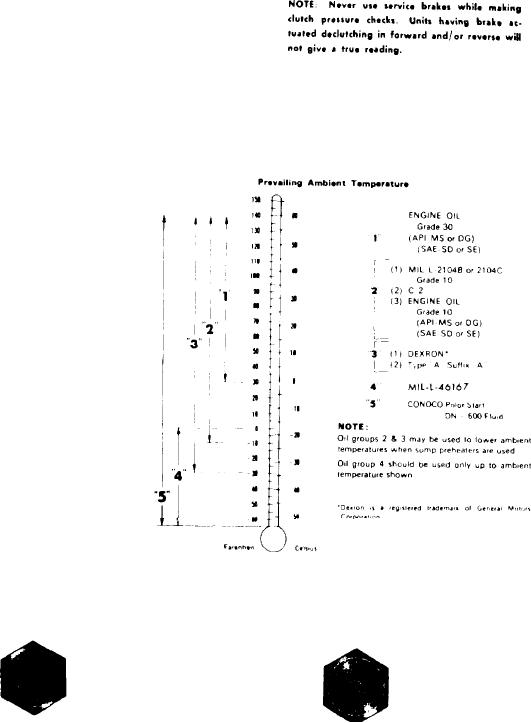

RECOMMENDED LUBRICANTS FOR CLARK POWER SHIFTED TRANSMISSION

See Lube Chart.

AND TORQUE CONVERTERS

CAPACITY

Consult Operator's Manual on applicable

machine model for system capacity. Torque

Converter, Transmission and allied hydraulic

system must be considered as whoIe to

determine capacity.

CHECK PERIOD Check oil level DAILY with engine running

at 500-600 RPM and oil at 180 to 200 F.

[82,2,-93,3 C]. Maintain oil level to FULL

mark.

DRAIN PERIOD Every 250 hours, change oil filter element.

Every 500 hours, drain and refill system as

follow: Drain with oil at 150 to 200 F.

[65,6 - 93,3 C].

Drain transmission and remove sump

(a)

screen. Clean screen thoroughly and

replace, wing new gaskets.

Drain oil filters, remove and discard

(b)

filter elements. Clean filter shells and

install new elements.

Refill transmission to LOW mark.

(c)

Run engine at 500-600 RPM to prime

(d)

converter and lines.

Recheck level with engine running at

(e)

500-400 RPM and add oil to bring

level to LOW mark.. When oil tempera.

ture is hot (180-200F.) [82,2-93, 23C]

make final oil level check. BRING OIL

LEVEL TO FULL MARK.

TORQUE IN (LBS.-FT.)

BOLTS, CAPSCREWS, STUDS AND NUTS

Grade 5 Identification, 3 Radial

Grade 8 Identification, 6 Radial

Dashes 120 Apart on Head of Bolt

Dashes 60 Apart on Head of Bolt

LUBRICATED OR PLATED

Grade 5

Grade 8

Nominal

Thread Size

FINE THREADS

COARSE THREADS

FINE THREADS

COARSE THREADS

[3,2-3,4m.kg]

23-25

26-29

[3,6-4,0m.kg]

3/8

37-41

[5,1-5,6m.kg]

33-36

[4,6-4,9m.kg]

[5,1-5,6m,kg]

37-41

41-45

[5,7-6,2m.kg]

7/16

58-64

[8,0-8,8m.kg]

52-57

[7,2-7,8m.kg]

[7,9-8,7m.kg]

57-63

90-99

[12,4-13,6m.kg]

64-70

[8,8-9,6m.kg]

1/2

80-88

(11,-12,1m.kg]

[11,3-12,4m.kg]

82-90

128-141

91-100

[12,6-13,8m.kg]

[17,7-19,4m.kg]

9/16

115-127

[15,9-17,5m.kg]

-16-