175B TRACTOR SHOVEL

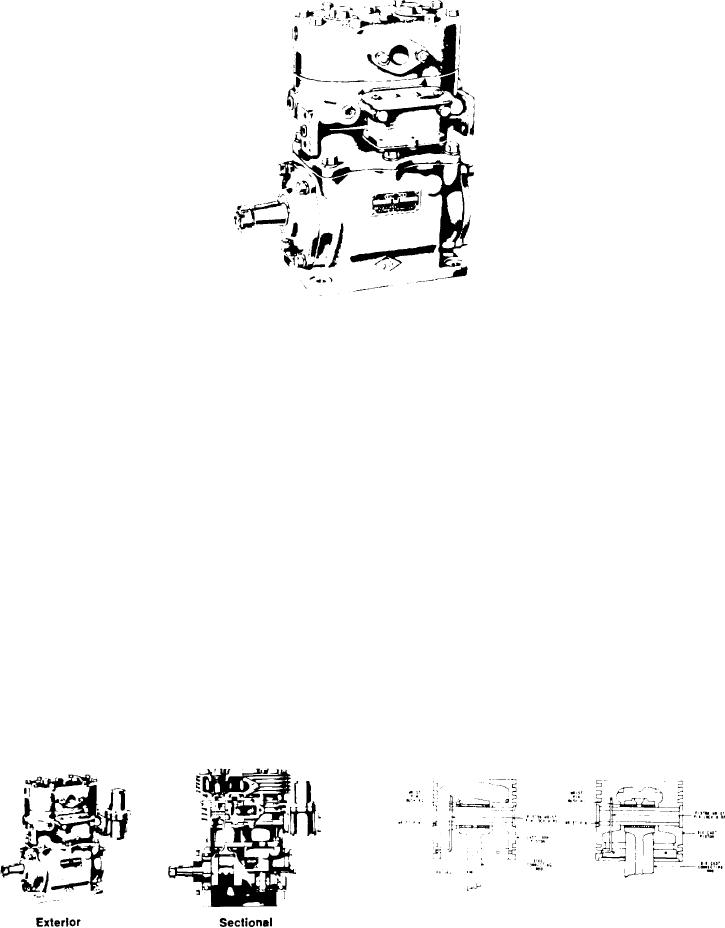

BENDIX WESTINGHOUSE MODEL 500 AIR COMPRESSOR

moving parts from the engine on which it is

DESCRIPTION AND

mounted.

GENERAL OPERATION

Oil is forced through the oil passage in the crank-

The function of the air compressor is to build up

shaft and out around each connecting rod journal.

a n d maintain the air pressure required to operate

The turning motion of the cranskshaft throws the oil

air power devices and air brake or air auxiliary

that is forced out at the journals, against the cylin-

systems.

d e r bores and crankcase walls, lubricating the

bores and crankshaft bearings.

The Model 500 compressor is a single stage re-

ciprocating piston type compressor with two cylin-

The wrist pins and wrist pin bushings are lubri-

ders. The rate capacity of all Bendix-Westinghouse

cated in two ways depending upon the type con-

compressors is their piston displacement in cubic

necting rods used (Fig. 2). If forged steel rods are

feet per minute when operating at 1,250 rpms. The

used, the oil is forced from the crankshaft through

B e n d i x - W e s t i n g h o u s e Model 500 is rated at 12

a drilled passage in the rod to the wrist pins and

cubic feet per minute (see figure number 1).

bushings. The other type connecting rod which is

currently being used is the aluminum die cast type.

Bendix-Westinghouse

compressors have auto-

The die cast type rod is not drilled between the

matic type inlet valves.

Their unloading mechan-

crankshaft journal and wrist pin connections, but is

i s m s are located in the

cylinder block and they

drilled at the top of the rod. The wrist pins and bush-

have no external moving

parts.

ings are lubricated by oil dripping from a drip-boss

on the piston into a "catch-funnel" at the top of the

The compressor is engine lubricated, which

rod and through the drilled passage to the bushings

means that it obtains the oil necessary to lubricate

and pins.

Figure 2

Pistons and Connecting Rods

Figure 1 Tu-Flo 500

[74]