valve, and on top of the piston (Fig. 4). As the piston

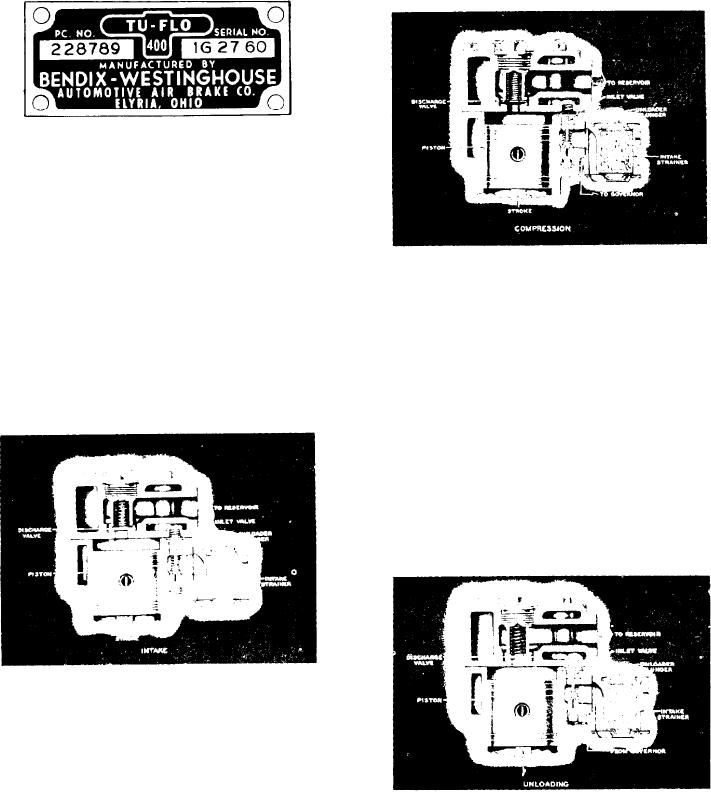

A nameplate is attached to the crankcase of all

starts its upward stroke, the air that was drawn in

compressors. It shows the piece number, type and

on the down stroke is being compressed. Now, air

serial number (Fig. 3). A nameplate with a black

pressure on top of the inlet valve plus the force of

background denotes a new compressor, whereas a

its spring, returns the inlet valve to its seat. The

nameplate with a red background designates that

piston continues the upward stroke and compresses

the compressor is a factory reconditioned unit. All

the air sufficiently to overcome the discharge valve

c o m p r e s s o r s are identified by the piece number

spring and unseat the discharge valve. The com-

which is the number to use when reference is made

pressed air then flows by the open discharge valve,

t o a particular compressor. The type and serial

into the discharge line and on to the reservoirs (Fig.

number is supplementary information.

5).

Figure 3

Compressor Nameplate

OPERATION

GENERAL

Figure 5

The compressor runs continuously while the

As the piston reaches the top

of its stroke and

engine is running but actual compression of air is

starts down, the discharge valve

spring returns the

controlled by a governor which stops or starts the

discharge valve to its seat. This

prevents the com-

c o m p r e s s i o n of air by loading or unloading the

pressed air in the discharge line

from returning to

compressor in conjunction with its unloading mech-

the cylinder bore as the intake

and compression

anism. This is done when the air pressure in the

cycle is repeated.

system reaches the desired maximum or minimum

pressures.

NON-COMPRESSION (Unloaded)

When the air pressure in the reservoir reaches

the high pressure setting of the governor, the gov-

ernor opens, allowing air to pass from the reservoir

through the governor and into the cavity beneath

the unloader pistons. This lifts the unloader pistons

and plungers. The plungers move up and hold the

inlet valves off their seats (Fig. 6).

Figure 4

INTAKE AND COMPRESSION (Loaded)

During the down stroke of the piston, a slight

vacuum created above the piston causes the inlet

valve to move off its seat. Atmospheric air is drawn

in through the compressor intake, by the open inlet

Figure 6

[75]