TM 5-3805-258-10

MOVING AND STOPPING THE VEHICLE

6. Depress the accelerator pedal.

Drive the machine forward for best visibility

and control.

CAUTION

For operator safety and comfort and maxi-

mum service life of power train components,

deceleration and /or braking is recommended

before any directional shifts are made.

Emergency Brake System

WARNING

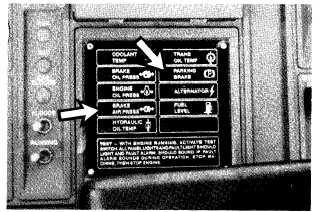

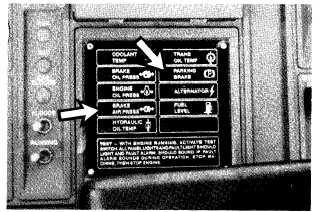

If the brake system air pressure drops be-

low normal operating pressure, a warning

horn will sound. The low brake pressure

and the parking brake indicators on the

operator’s panel will light up. The fault

light will start flashing.

If the pressure drops further, the parkin-

g/emergency

brake

will

apply

automatically and the transmission will

shift to neutral.

Be prepared for a sudden stop. Correct the

reason for the loss of air pressure. Do not

move the machine without normal air

pressure.

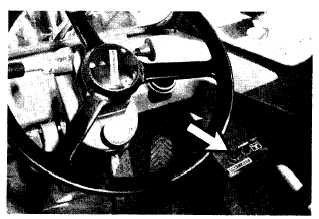

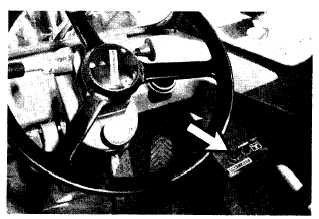

In an emergency, the machine can be

moved with the parking/emergency brake

applied, with the engine running, by

holding the shift lever in 1st speed, The

lever and transmission will return to

NEUTRAL immediately when the lever is

released,

CAUTION

Moving the machine with the parking /emer-

gency brake applied can cause excessive

wear or damage to the brake. If necessary,

have the brake repaired before operating the

machine.

Loss of brake oil or air pressure will

cause the brake indicators on the operator

panel to light up. The emergency brake

will automatically engage and stop the

machine.

The fault light will also flash when the

monitor system lights go on.

44