TM 5-3805-258-24-1

9904 DIRECT INJECTION VEHICULAR ENGINE

SPECIFICATIONS

WITH SCROU FUEL SYSTEM

(1)

(2)

(3)

(4)

(5)

(6)

(7)

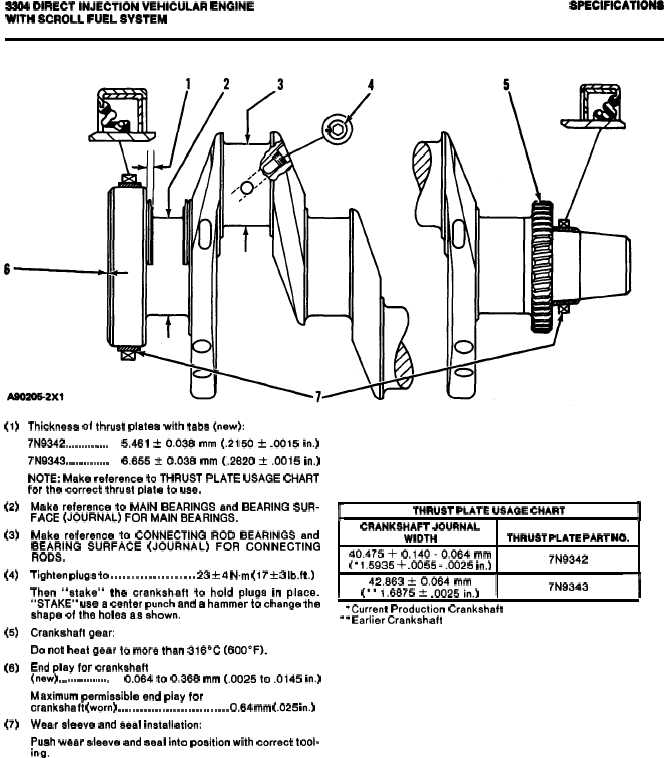

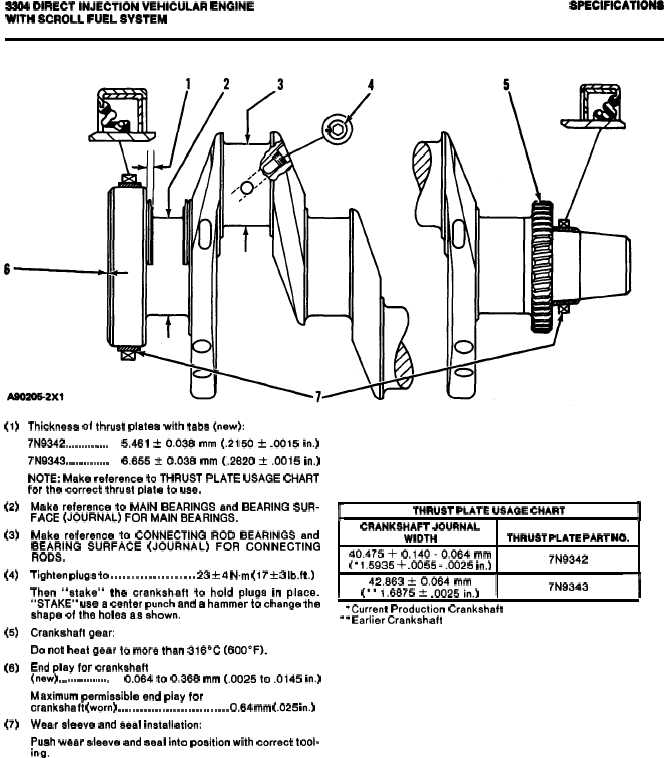

CRANKSHAFT

Thickness of thrust plstee with tsbs (new):

7N9342 . . . . . . . . . . . . . .

5,461 t 0.036 mm (.2150 * .0015 in.)

7N9343 . . . . . . . . . . . . . .

6.655 * 0.038 mm (.2620 * .0015 in.)

NOTE: Make reference to THRUST PLATE USAGE CHART

for the correct thrust plate to use.

Make reference to MAIN BEARINGS and BEARING SUR-

FACE (JOURNAL) FOR MAIN BEARINGS.

Make reference to CONNECTING ROD BEARINGS and

BEARING SURFACE (JOURNAL) FOR CONNECTING

RODS.

Tighten pluga to . . . . . . . . . . . . . . . . . . . . 23 ~ 4 N.m (17 * 3 Ib.ft.)

Then “stake” the crankshaft to hold plugs in place.

“STAKE” uses center punch and a hammer to change the

ahape of the holes as shown.

Crankshaft gear:

Do not heat gear to more than 316°C (600”F).

End play for crankshaft

(new) . . . . . . . . . . . . . . . . .

0.064 to 0.366 mm (.0025 to .0145 in.)

Maximum permissible end play for

crankshaft (worn) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.64 mm (.025 in.)

Wear sleeve and seal installation:

Push wear aleeve and seal into position with correct tool-

ing.

r

THRUST PLATE USAGE CHART

I

CRANKSHAFT JOURNAL

WIDTH

THRUST PLATE PART NO.

40.475 + 0.140-0.064 mm

(” 1.5935 + .0055 -.0025 in.)

7N9342

I

42.863 t 0.064 mm

(*• 1.6875 f .0025 in.)

I

7N9343

‘1

“Current Production Crankshaft

‘ l Earlier Crankshaft

2-20