TM 5-3805-258-24-1

3304 DIRECT INJECTION VEHICULAR ENGINE

SPECIFICATIONS

WITH SCROLL FUEL SYSTEM

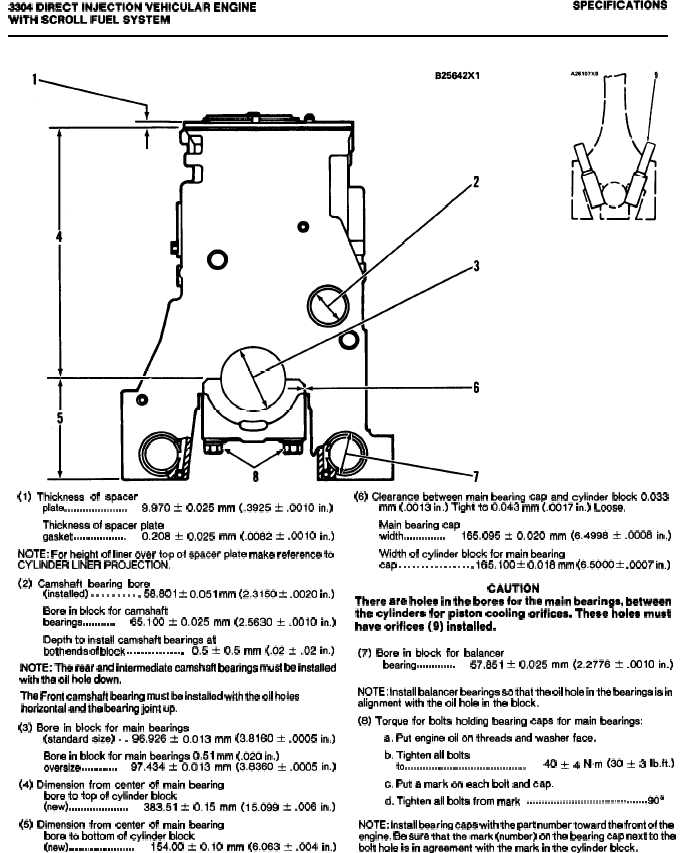

CYLINDER BLOCK

(1) Thickness of spscer

plate . . . . . . . . . . . . . . . . . . . . .

9.970 ~ 0.025 mm (.3925 k .0010 in.)

Thickness of spacer plate

gaaket . . . . . . . . . . . . . . . . . .

0.208 & 0.025 mm (.0082 * .0010 in.)

NOTE: For height of liner over top of spacer plate make reference to

CYLINDER LINER PROJECTION.

(2) Camshaft bearing bore

(installed) . . . . . . . . . . 58.801 * 0.051 mm (2.3150 * .0020 in.)

Bore in block for camshaft

bearings . . . . . . . . . . .

65.100 * 0.025 mm (2.5630 t .0010 in.)

Depth to install camshaft bearings at

both ends of block . . . . . . . . . . . . . . . .

0.5 * 0.5 mm (.02 * .02 in.)

NOTE: The rear and intermediate camshaft bearings rrwat be installed

with the oil hole down.

The Front camshaft bearing must be installed with the oil holee

horizontal and the bearing joint up.

(3) Bore in block for main bearings

(standard size) . . 96.926 t 0.013 mm (3.8160 * .0005 in.)

Bore in block for main bearings 0.51 mm (.020 in.)

overeize . . . . . . . . . . . .

97.434 * 0.013 mm (3.8360 * .0005 in.)

(4) Dimension from center of main bearing

bore to top of cylinder block

(new) . . . . . . . . . . . . . . . . . . . .

383.51 & 0.15 mm (15.099 t .006 in.)

(5) Dimeneion from center of main bearing

bore to bottom of cylinder block

(new) . . . . . . . . . . . . . . . . . . . . . .

engine. Be sure tha[the’mark (number) on the bearing cap next to the

154.00 * 0.10 mm (6.063 * .004 in.)

bolt hole is in agreement with the mark in the cylinder blcck.

(6) Clearance between main bearing cap and cylinder block 0.033

mm (.0013 in.) Tight to O.O43 mm (.0017 in.) Loose.

Main bearing cap

width . . . . . . . . . . . . . .

165.095 t 0.020 mm (6.4998 f .0008 in.)

Width of cylinder block for main bearing

cap . . . . . . . . . . . . . . . . . 165.100 t 0.018 mm (8.5000 * .0007 in.)

CAUTION

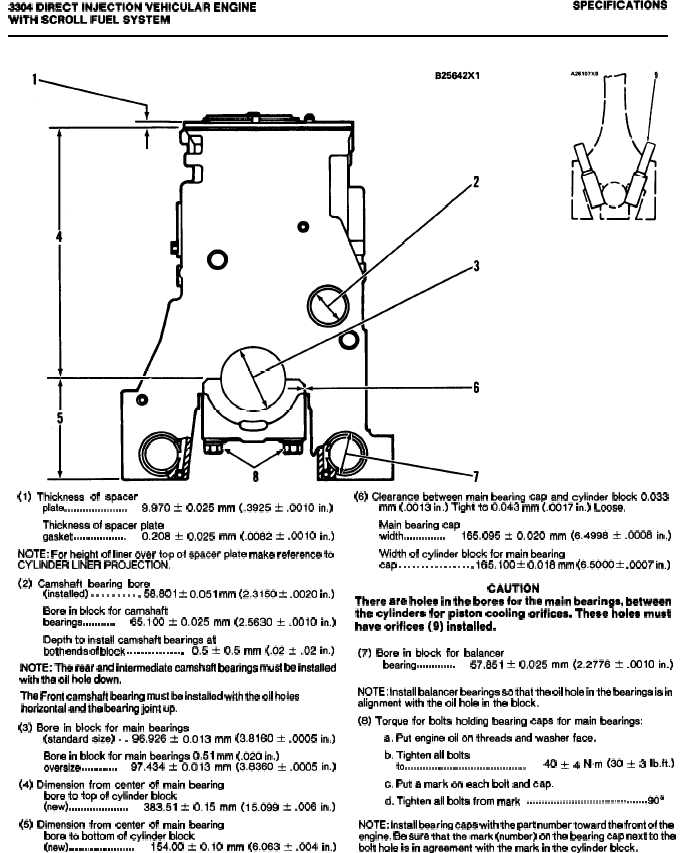

There are holee in the bores for the main bearinga, between

the cylinders for piston cooling orifices. These holes must

have orifices (9) installed.

(7) Bore in block for balancer

bearing . . . . . . . . . . . . .

57.851 * 0.025 mm (2.2776 f .0010 in.)

NOTE: Install balancer bearings so that the oil hole in the bearings ie in

alignment with the oil hole in the block.

(8) Torque for bolts holding bearing caps for main bearings:

a. Put engine oil on threads and washer face.

b. Tighten all bolts

to . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40 ~ 4 N.m (30 & 3 Ib.ft.)

c. Put a mark on each bolt and cap.

d. Tighten all bolts from mark

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90°

NOTE: Install bearing caps with the part number toward the front of the

2-16