TM 5-3805-258-24-1

H Y D R A U L I C

S Y S T E M

S Y S T E M S

O P E R A T I O N

If the pressure of the oil in the circuit through inlet

opening (1) and in the chamber for spring (9) gets as

high as the setting of the relief valve, the oil moves

pilot valve (3) open. The oil in the spring chamber

goes, through the open pilot valve and through pas-

sage (8) to the tank. Now, with only the force of

spring (9) on valve (2), the pressure of the oil in inlet

opening (1) moves valve (2) far enough to let the oil

in the inlet opening (and circuit) go through outlet

openings (7) to the tank. When the oil in the circuit

can go through inlet opening (1) and then through

outlet openings (7), the pressure of the oil can not

increase to a pressure higher than the setting of the

relief valve.

The pressure setting of the relief valve can be

changed by either an increase or a decrease in the

force of the spring that keeps pilot valve (3) closed.

Remove plug (6) and turn plunger (5) clockwise for

an increase or counterclockwise for a decrease in the

pressure setting of the relief valve.

Relief Valves For Tilt And Attachment

Cylinders

There is a relief valve in each of these circuits:

head end of the tilt cylinder, rod end of the tilt

cylinder, head end of attachment or third cylinders

and rod end of attachment cylinders. These valves

are the same in construction and operation. These

valves are different in construction from the main

relief valve, but their operation is similar.

When either valve spool (tilt control or third con-

trol) is in HOLD position, the relief valves in the

head and rod ends limit the maximum amount of

pressure in the cylinder lines. If an outside (external)

force on the bucket or attachment becomes too high,

the relief valve will permit movement of the cylinder

piston. This prevents damage to the machine

components.

The relief valve for the rod end of the tilt cylinder

also releases the rod end pressure when the lift arms

are lifted with the bucket fully dumped and the tilt

control valve spool is in HOLD position.

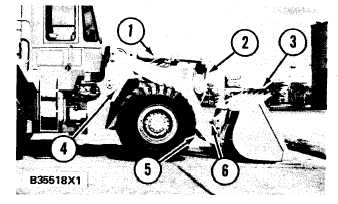

BUCKET CONTROL GROUP

The bucket control group gives a way to control the

operation of bucket (3). This group is made up of

two lift cylinders (4), one tilt cylinder (1), lift arm

assembly (5), lever (2) and link (6). This type of

linkage is known as Z-bar linkage because of the Z

formed by the tilt cylinder, lever and link. Tilt cy-

linder (1), lift cylinders (4) and lift arm assembly (5)

are fastened to the loader frame by pins.

B U C K E T C O N T R O L G R O UP

1. Tilt cylinder. 2. Lever. 3. Bucket. 4. Lift cylinders (in-

side loader frame). 5. Lift arm assembly. 6. Link (between

the lift arm assembly).

When pressure oil is sent to the head end of the lift

cylinders, lift arm assembly (5) is lifted. When pres-

sure oil goes to the rod end of the lift cylinders (4),

the lift arm assembly is lowered.

The bucket will tilt back when pressure oil is sent

to the head end of tilt cylinder (1). The bucket will

dump when pressure oil goes to the rod end of the tilt

cylinder.

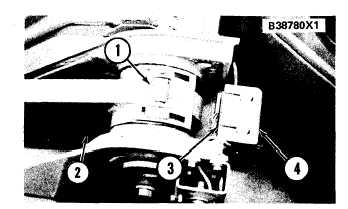

LIFT KICKOUT

P A R T S T O A C T I V A T E T H E L I F T K I C K O U T

1. Magnet assembly. 2. Lift arm on left side. 3. Electric

switch in the holder. 4. Holder for electrical switch.

3-109