TM 5-3805-258-24-1

H Y D R A U L I C

S Y S T E M

S Y S T E M S O P E R A T I O N

The lift kickout is electric and its action moves the

lift control lever from the detent on the RAISE posi-

tion to the HOLD Position just before the lift arms

get to the top of their travel.

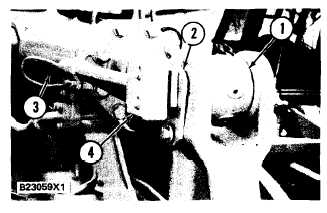

When the rods in the lift cylinders, that move the

lift arms, get near their full extension, magnet (1) on

the left side lift arm (2) goes toward holder (4).

Switch (3), in holder (4) on the loader frame, is a

solid state switch. The magnet (field) closes the

switch to make a ground in the switch. The ground is

for the circuit of lift kickout solenoid (8). As the lift

arms are moved higher, magnet (1) moves under

switch (3) and the magnet (field) closes the circuit in

the switch, for solenoid (8). Now that solenoid (8)

has a closed circuit, the solenoid activates and pulls

the roller away from detent (5). With no roller in the

detent to keep the lift control lever in the RAISE

position, the spring in the pilot valve moves the lift

stem and the lift control lever to the HOLD position.

With the lever and lift stem in the HOLD position,

the movement of the lift cylinder rods stop before the

pistons on the rods hit the ends of the lift cylinders.

C O N T R O L L E V E R S A N D L I N K A G E

I N H O L D P O S I T I O N

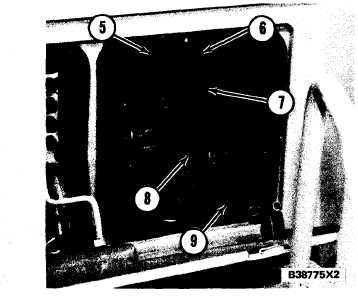

5. Detent for lift and float. 6. Detent for tilt back. 7. Spring

(for lift detent roller.) 8. Lift kickout solenoid. 9. Bucket

positioner

solenoid.

When magnet (1) closes the circuit in switch (3), it

is not closed very long and the circuit for lift kickout

solenoid (8) is again open. The solenoid releases the

roller when the circuit is open. Now, spring (7) will

move the roller into detent (5), to hold the lift control

lever in a position, when it is moved to either RAISE

or FLOAT position. Magnet (1) must move away

from switch (3) and then be moved under switch (3)

again to close the switch (circuit), but only for ap-

BUCKET POSITIONER

The bucket positioner is electric. Its action moves

the tilt control lever from the detent on the TILT

BACK position to the HOLD position at the correct

angle to dig as the bucket moves from dump to tilt

back.

P A R T S T O A C T I V A T E T H E B U C K E T P O S I T I O N ER

( T Y P I C A L)

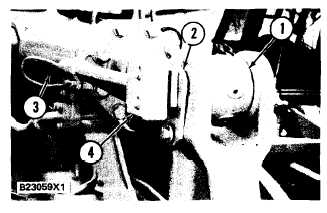

1. Rod. 2. Magnet assembly (on tilt lever arm). 3. Tilt

cylinder. 4. Electric switch (in cover assembly on the tilt

c y l i n d e r ) .

The rod moves farther out of the tilt cylinder to

move the bucket away from dump to bucket tilt back.

When rod (1) moves out of tilt cylinder (3), magnet

(2) on the tilt lever goes toward bucket positioner

switch (4). Switch (4), in the bucket positioner

switch assembly on tilt cylinder (3), is a solid state

switch. In one direction (toward tilt back), the mag-

net (field) closes the switch to make a ground for the

solenoid circuit. In the other direction (toward

dump), the magnet (field) opens the switch to open

the circuit (no ground).

As the tilt cylinder rod moves the bucket from

dump toward tilt back, magnet (2) moves almost past

switch (4) and the magnet (field) closes the circuit

for bucket positioner solenoid (9). Now that solenoid

(9) has a closed circuit, the solenoid activates and

pulls the roller away from detent (6). With no roller

in the detent to keep the tilt control lever in TILT

BACK position, the spring in the pilot valve moves

the valve stem and the tilt control lever to the HOLD

position. Now, the movement of the tilt cylinder rod

stops and the movement of the bucket stops at the

correct angle to dig. Solenoid (9) keeps activated and

there is no detent for the TILT BACK position of the

tilt control lever. The lever must be held in any

position except HOLD.

When the rod moves into the tilt cylinder to move

the bucket from tilt back to dump, magnet (2) moves

past switch (4). The magnet (field) opens the circuit

to solenoid (9) when it passes switch (4) and the

proximately one-half second.

solenoid is not activated. Now, when the tilt control

3-110