FLOW CONTROL VALVE.

Controls flow of oil to

flow from hydraulic pump steering section to

TM 5-3805-262-20

steering gear, in effect, reducing oil

approximately 13 gpm. Relief valve lo-

cated in flow control valve and is not adjustable; setting is 2500 ±100 psi.

CHECK VALVE.

Prevents oil from auxiliary steering motor and pump entering hydraulic

pump when auxiliary steering motor and pump operating.

AUXILIARY STEERING MOTOR AND PUMP.

Automatically provides steering hydraulic power

if engine shuts down. Includes flow switch and auxiliary steering check valve. Check

valve prevents oil from hydraulic pump entering auxiliary steering pump when hydrau-

lic pump is operating. If engine stops, hydraulic pump stops pumping oil. Flow

switch will operate to electrically activate auxiliary steering control circuit

(page 1-18), When control circuit is activated, auxiliary steering motor and pump

will operate providing hydraulic power to steering system.

STEERING CYLINDER ASSEMBLIES.

Two used, one mounted on each side of loader. Each

end of cylinder attached to front and rear chassis.

1-28. FRAME AND TOWING ATTACHMENTS

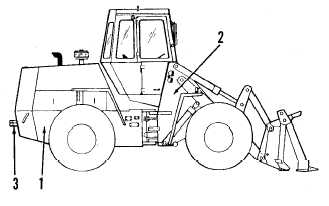

1. REAR CHASSIS ASSEMBLY.

Constructed of heavy duty steel. Includes (1) frame stops

constructed of heavy duty rubber which provide stops when chassis´ are turned to

their maximum travel. (2) Transport/service link used to prevent front chassis from

pivoting when loader raised from ground or when maintenance performed. (3) Engine

side panels. (4) Trunnion lubrication fittings installed on left side of loader and

connected to trunnion via grease hoses. (5) Lift and tiedowns welded to chassis at

rear. (6) Trunnion to which rear axle is fastened. Trunnion pivots at center to en-.

sure four wheel contact at all times on uneven terrain.

2. FRONT CHASSIS ASSEMBLY.

Constructed of heavy duty steel. Includes (1) steps for

access to cab; (2) frame stops constructed of heavy duty rubber which provide stops

when chassis´ are turned to their maximum travel. (3) Tiedowns and lifting brackets

welded to chassis. (4) Chassis spindles on which front and rear chassis’ pivot when

loader is turned.

3. DRAWBAR PIN. Located at rear of loader. Used to attach tow bar to loader for

either towing loader or another vehicle.

1-27