TM 5-3805-262-20

4-2. FUEL SYSTEM MAINTENANCE (CONT)

h. A c c e l e r a t o r ( c o n t ).

ADJUSTMENTS (SHEET 1 OF 2)

(1)

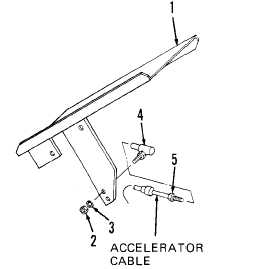

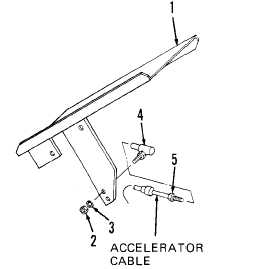

Beneath cab deck, check that accelerator pedal (1) lever is contacting

f r o n t o f s l o t i n f l o o r p l a t e . I f n e c e s s a r y:

(a) Remove nut (2) and lock washer (3) and disconnect ball joint (4) from

a c c e l e r a t o r p e d a l l e v e r.

(b) Turn ball joint (4) and nut (5) to mid-

point of threaded shaft of accelerator

c a b l e.

( c ) C o n n e c t b a l l j o i n t ( 4 ) t o a c c e l e r a t or

pedal (1) lever. Reinstall lock washer (3)

and nut (2).

(d) Check that lever is contacting front of

s l o t i n f l o o r p l a t e.

I f l e v e r i s s t i l l n ot

c o n t a c t i n g f r o n t o f s l o t i n f l o o r p l a t e ,

repeat steps (a) through (c) above except

t u r n b a l l j o i n t f a r t h e r o f f a c c e l e r a t o r

cable threaded shaft.

( e ) T i g h t e n n u t ( 5 ) a g a i n s t b a l l j o i n t ( 4 ).

(2)

Start engine and operate until normal operating temperature is reached.

Keep clear of fan and belts while engine is operating. Failure to do so

c o u l d c a u s e s e r i o u s i n j u r y .

I f y o u a r e i n j u r e d , o b t a i n m e d i c a l a id

immediately.

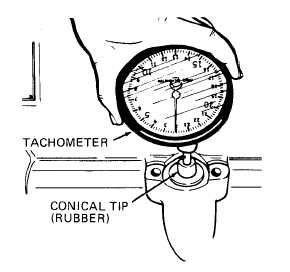

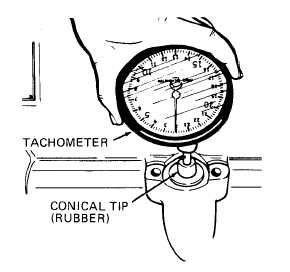

( 3 ) A i m f l a s h i n g l i g h t o f s t r o b o s c o pe

tachometer on crankshaft pulley.

A d j u s t f l a s h i n g r a t e u n t i l c r a n k s h a ft

pulley appears stationary, then read

engine rpm from meter on stroboscope

tachometer. If stroboscope tachometer

is not available, press tachometer

against engine tachometer drive shaft

as shown. When tachometer pointer

stops moving, note indication.

Remember, tachometer drive shaft

operates at half engine speed. Double

tachometer indication to obtain

engine rpm. Rpm indication should be

700 to 750. If rpm indication is not

as specified, perform step (4) below

otherwise go to step (5) below.

4-64