TM 5-3805-262-20

ADJUSTMENTS ( SHEET 2 OF 2)

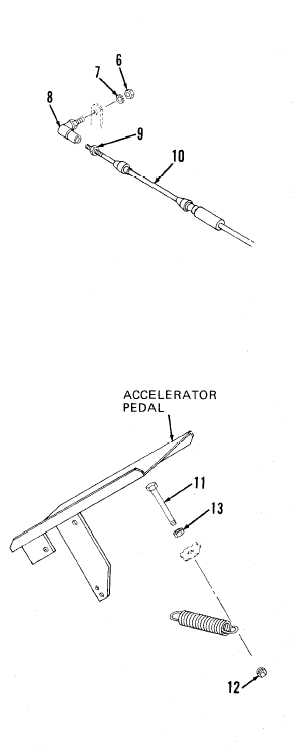

(4)

I f n e c e s s a r y , a t f u e l i n j e c t i o n

pump, remove nut (6) and lock

washer (7) and disconnect ball

joint (8). To increase rpm,

turn nut (9) and ball joint

f a r t h e r o f f a c c e l e r a t o r c a b le

(10) threaded shaft; to

decrease rpm, turn nut (9) and

b a l l j o i n t f a r t h e r on

accelerator cable (10) threaded

shaft. Tighten nut (9) against

b a l l j o i n t ( 8 ) .

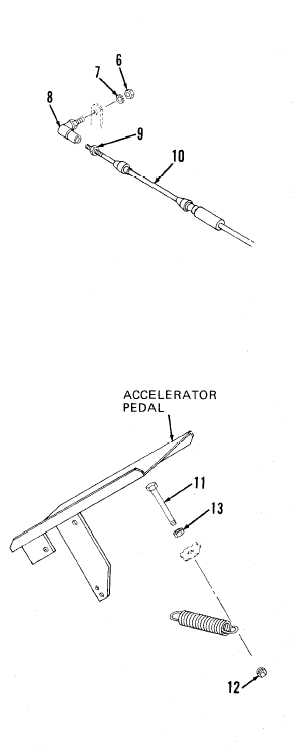

( 5 ) W h i l e a n a s s i s t a n t s l o w l y d e-

p r e s s e s a c c e l e r a t o r p e d a l u n t il

it contacts capscrew (11) with

engine running, aim flashing

light of stroboscope tachometer

on crankshaft pulley. Adjust

flashing rate of stroboscope

tachometer until crankshaft

pulley appears stationary then

read engine rpm from meter on

stroboscope tachometer. If

stroboscope tachometer is not

available, press tachometer

against engine tachometer drive

shaft. When tachometer pointer

stops moving, note indication .

Remember, tachometer drive

shaft operates at half engine

speed. Double tachometer

indication to obtain engine

rpm. Rpm indication should be

2300 to 2340. If rpm indication

is not as specified, perform

step (6) below otherwise

proceed to step (7) below.

( 6 ) I f n e c e s s a r y , l o o s e n n u t s ( 12

and 13) and turn capscrew (11)

clockwise to increase rpm or

counterclockwise to decrease

rpm when accelerator pedal is

completely depressed. Tighten

nuts (12 and 13) when proper

i n d i c a t i o n i s o b t a i n e d .

(7) Reconnect tachometer cable to tachometer drive assembly (page 5-67).

( 8 ) R e i n s t a l l e n g i n e r i g h t s i d e p a n e l s ( p a g e 9 - 1 7 ).

4-65