TM 5-3805-262-20

5-8. SENDING UNITS AND WARNING SWITCHES MAINTENANCE (CONT)

b. Fuel Level Sending Unit (cont).

INSPECTION, TESTING, AND REPAIR

(1)

(2)

(3)

( 4)

( 5)

Inspect wiring harness terminal (3) wire for cracked or broken insulation

or broken wire strands at connection to terminal. Repair cracked or bro-

ken insulation by applying insulation tape to area. If broken wire

strands are seen, cut wire as close to terminal as possible. Strip 1/4

inch insulation from end of wire taking care not to cut through wire then

crimp new terminal securely onto wire.

Inspect wire (11) for cracked or broken insulation or broken wire strands

at connection to terminal. Repair cracked or broken insulation by apply-

ing insulation tape to area.

If broken wire strands are seen, replace

w i r e .

Inspect fuel level sending unit (12) for cracks, breaks, damaged threads,

distortion, broken or missing terminal, bent float rod, or other damage.

Lower float into a container of clean diesel fuel and check for leakage

as indicated by bubbles. Replace if any of these conditions are seen.

Inspect remaining parts for cracks, breaks, distortion, or damaged

t h r e a d s ; replace as necessary.

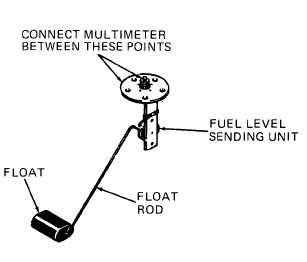

Test fuel level sending unit (12)

( a )

Connect multimeter between fuel

as shown below.

(b)

Hold fuel level sending unit

i n v e r t i c a l p o s i t i o n as

shown.

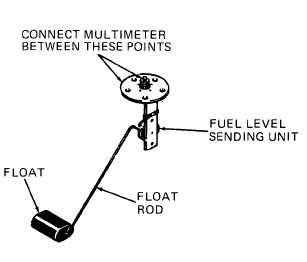

(c)

Slowly raise sending unit

float and float rod while

watching multimeter. Multi-

meter indication should

smoothly increase from 0-3

ohms at bottom position of

float to 84-92 ohms at top

p o s i t i o n o f f l o a t.

(d)

Disconnect multimeter from

fuel level sending unit.

( e )

Replace fuel level sending unit

above are not obtained.

as follows:

level sending unit body and terminal

if multimeter indications in step (c)

5-118