TM 5-3805-262-20

6-1. TRANSMISSION MAINTENANCE (CONT)

a. T r a n s m i s s i o n ( c o n t ).

( 2 ) S e r v i c i n g.

This task covers servicing of transmission. Transmission ser-

vicing consists of checking oil level, d r a i n i n g a n d r e f i l l i n g o i l , a n d r e p l a c i ng

transmission oil filter. Check transmission oil level every 50 hours of operation or

every week; change transmission oil, clean transmission suction strainer and brea-

t h e r , and install a new oil filter after the first 500 hours of operation and every

500 hours of operation afterwards.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Fixed open end wrench set

Socket wrench set, 3/8 inch drive

Container, ten gallon capacity

MATERIALS/PARTS: Clean cloths

(Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

Transmission

Gasket (FSCM

Filter (FSCM

REFERENCES: LO 5-3805-262-12

o i l ( r e f e r t o c u r r e n t l u b r i c a t i o n o r d e r)

73342 PN 688702)

10988 PN A61234)

NOTE

PRELIMINARY PROCEDURE: Engine side panels removed (page 9-14).

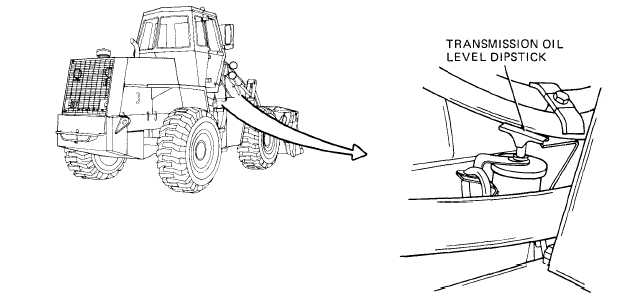

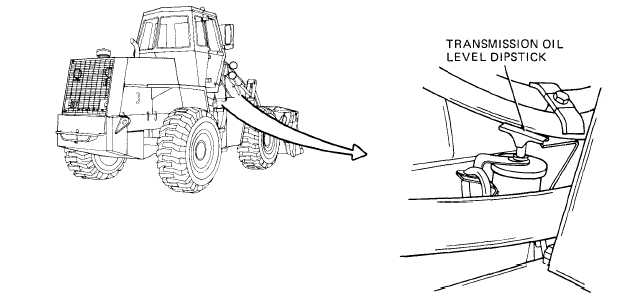

OIL LEVEL CHECK (SHEET 1 OF 2)

( a ) U n l o c k t r a n s m i s s i o n d i p s t i c k.

(b) Start engine and operate at idle speed. If CONV TEMP gage pointer is not

in green area, go to step (c) below otherwise go to step (g) below.

6 - 4