TM 5-3805-262-20

INSPECTION (SHEET 3 OF 3)

(7)

(8)

(9)

(10)

(11)

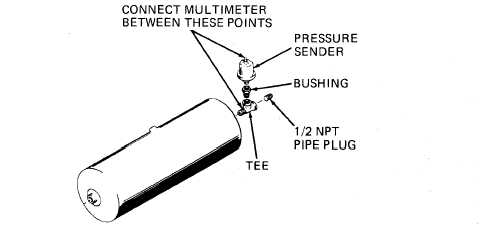

I n s t a l l t e e , b u s h i n g , p r e s s u r e s e n d e r , a n d 1 / 2 N P T p i p e p l u g i n a i r r e s-

e r v o i r a s s h o w n b e l o w . D o n ’ t r e m o v e p a r t s i n s t a l l e d i n s t e p ( 6 ) a b o v e e x -

cept 1/2 NPT pipe plug. Connect multimeter between points shown below.

Multimeter should indicate between zero to 6 ohms. If not, replace pres-

sure sender.

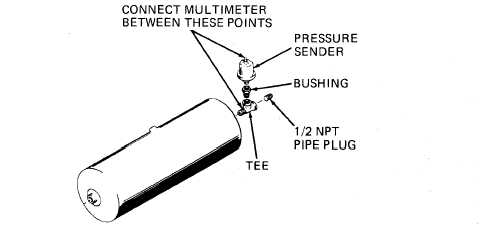

Ensure that drain valve in air reservoir is closed. Connect a source of

compressed air to tee in which safety valve is installed and slowly in-

crease air pressure applied to air reservoir while watching multimeter.

With zero psi applied , multimeter should indicate zero to 6 ohms; at 30

psi pressure multimeter should indicate 17 to 27 ohms; at 65 psi, 40 to

50 ohms; at 90 psi, 60 to 70 ohms; and at 120 psi, 80 to 96 ohms. Discon-

nect compressed air source and open drain valve to release air pressure,

Replace pressure sender if any of the above indications are not obtained.

R e m o v e a l l p a r t s i n s t a l l e d i n a i r r e s e r v o i r.

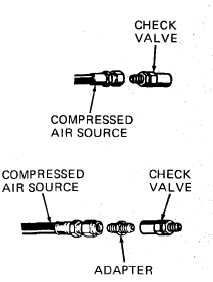

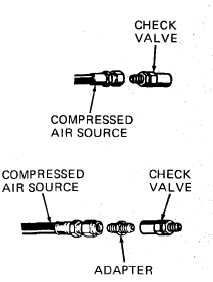

Connect a source of compressed air to check valve as

shown. Apply a maximum of 50 psi pressure and check

that air is vented through check valve. If not, re-

place check valve. Disconnect compressed air source.

Install adapter in check valve and connect a

source of compressed air to adapter as shown.

Apply a maximum of 100 psi pressure and check

that air is not vented through check valve. If

air is vented, check valve is defective and must

7-61