TM 5-3805-262-20

7-3. AIR BRAKE SYSTEM MAINTENANCE (CONT)

c. A i r R e s e r v o i r ( c o n t ).

INSPECTION

(2)

(SHEET 2 OF 3)

Connect a source of compressed air to 1/4 NPT air hose adapter and pres-

surize air reservoir to 100 psi . Immerse air reservoir in a tank of water

and check for air bubbles. Replace air reservoir if air bubbles are seen .

( 3)

(4)

( 5)

Remove air reservoir from tank, release air pressure, disconnect air

source, and remove pipe plugs and air hose adapter. Dry air reservoir

using clean cloths.

Check pressure sender (11), check valve (2), and safety valve (5) for

cracks, breaks, damaged threads, distortion, broken or missing terminals,

or other damage. Replace if any of these conditions are seen.

Check brackets (22) for cracks, breaks, distortion, or other damage. Re-

p l a c e i f n e c e s s a r y .

Inspect remaining parts for cracks, breaks, distortion, or damaged

threads; replace as necessary.

I n f o l l o w i n g s t e p d o n o t e x c e e d 1 6 0 p s i a i r p r e s s u r e a p p l i e d t o a ir

r e s e r v o i r .

To do so may cause serious

i n j u r y o r d e a t h d u e t o s a f e t y

v a l v e m a l f u n c t i o n i n g .

I f y o u a r e i n j u r e d , o b t a i n m e d i c a l a i d

immediately.

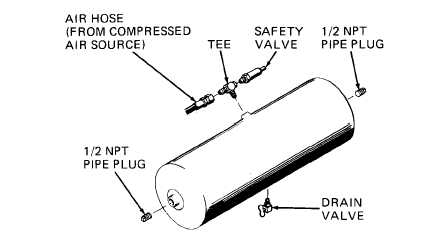

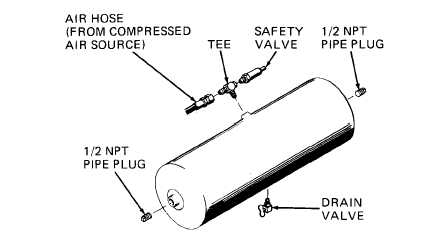

(6)

I n s t a l l p i p e p l u g s , t e e,

safety valve, and drain valve in air reservoir

as shown below. Ensure that drain valve is closed. Connect a source of

compressed air to tee and pressurize air reservoir to 150 psi while ob-

serving safety valve. Safety valve shall bleed off air when 150 ±10 psi

a i r p r e s s u r e i s r e a c h e d.

Open drain valve to release air reservoir air

pressure and disconnect compressed air source. If safety valve does not

o p e r a t e p r o p e r l y , r e p l a c e i t.

7-60