TM 5-3805-262-20

7-3. AIR BRAKE SYSTEM MAINTENANCE (CONT)

i. A l c o h o l E v a p o r a t o r . This task covers removal, disassembly, cleaning, inspec-

tion, reassembly, and installation of the alcohol evaporator and associated lines

a n d f i t t i n g s .

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Hand hammer, 16 ounces

Combination box and open end wrench set

Vise

R e t a i n i n g r i n g p l i e rs

1 / 8 i n c h d r i l l b it

D r i l l , 1 / 2 i n c h c a p a c i ty

Craftsman’s knife

Automotive Mechanic’s Tool Kit

Drive pin punch, 1/8 inch point

Drive pin punch, 3/8 inch point

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

Detergent (Appendix C, item 3)

REFERENCE: TM 5-3805-262-10

NOTE

PRELIMINARY PROCEDURE: Air reservoir drain valve opened, engine top hood

r e m o v e d ( p a g e 9 - 1 1 ), engine right side panels removed (page 9-14), and

air inlet hose disconnected from air compressor (page 7-108).

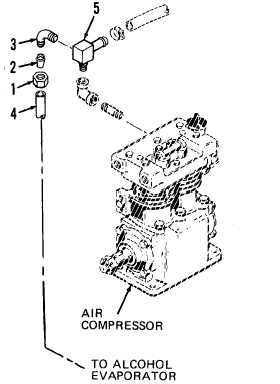

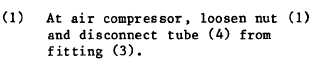

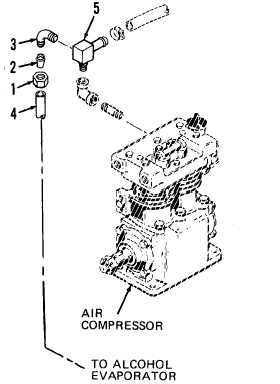

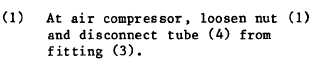

REMOVAL (SHEET 1 OF 2)

R e l i e v e a l l a i r p r e s s u r e b e f o r e

w o r k i n g o n a i r s y s t e m . F a i l u re

to do so could result in serious

i n j u r y .

I f y o u a r e i n j u r e d ,

obtain medical aid immediately.

(2) Loosen and remove fitting (3)

then elbow (5) from elbow

installed in air compressor port.

Change 1

7-117