TM 5-3805-262-20

SHEET 3 OF

( i )

( j )

(k)

( l )

(m)

(n)

(o)

(p)

(q)

3

Check that oil leakage is not seen at fitting (6), tube (7) connections,

and check valve (8) connections. Tighten fittings or connections as ne-

c e s s a r y.

Check tube (7) along its entire length for cracks, dents, bent condi-

tion, or other damage. Replace (page 8-14) as necessary.

Check that hose (9) connection at flow switch (10) and connections to

bottom of hydraulic oil cooler (11) are tight and that oil leaks are not

seen. If oil leakage is seen, tighten connections.

Cheek hose (9) along its entire length for cracks, splits, worn spots

due to chafing, or other damage. If any of these conditions are seen,

replace hose (page 8-14).

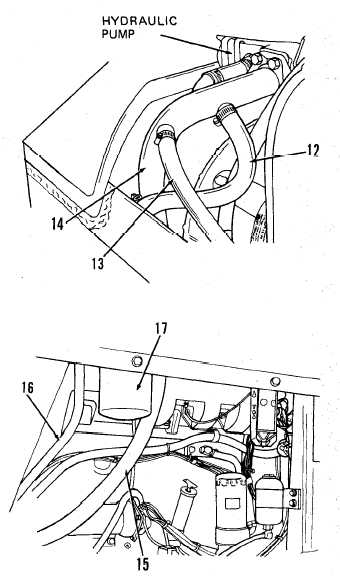

Check that hose (12 and 13)

connections at manifold (14)

a r e t i g h t a n d t h a t o i l l e a ks

are not seen. If oil leakage

is seen, tighten hose clamps .

If tightening hose clamps does

not stop leakage, replace

hoses and clamps (page 8-14).

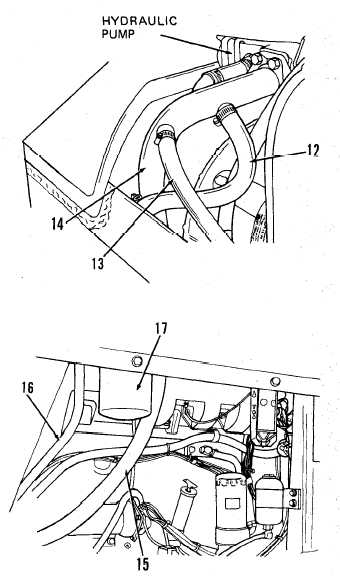

In engine compartment, check

that tube (16) and hose (15)

connections at steering hy -

d r a u l i c f i l t e r ( 1 7 ) h e a d a re

tight and oil leaks are not

s e e n . T i g h t e n f i t t i n g s i f o il

l e a k s a r e s e e n . I f t i g h t e n i ng

fittings does no good, replace

defective part (page 8-14).

Check tube (16) along its en-

t i r e l e n g t h f o r c r a c k s , d e n t s,

bent condition, or other

damage, Replace (page 8-14) as

n e c e s s a r y .

Check hose (15) along its

e n t i r e l e n g t h f o r c r a c k s ,

splits, worn spots due to

chafing, or other damage. If

any of these conditions are

seen, replace hose (page

8 - 1 4 ) .

I n s t a l l e n g i n e l e f t s i de

panels (page 9-17).

8-13