TM 5-3805-262-20

3-4. ENGINE TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

6. ENGINE STALLS FREQUENTLY OR DOES NOT DEVELOP FULL POWER (Cont).

Step 7.

Step 8.

Tell assistant to start and warm engine to operating temperature.

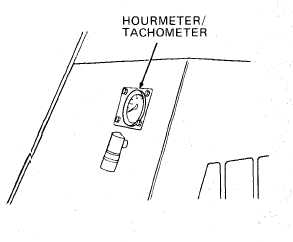

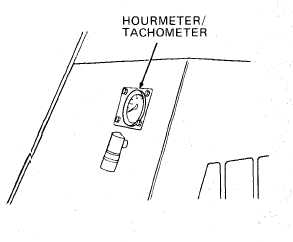

Watch hourmeter/tachometer and tell

a s s i s t a n t t o i d l e e n g i n e.

Record tachometer indication.

T e l l a s s i s t a n t t o d e p r e s s a c c e l e r a t o r

pedal until maximum governed speed of

2300 to 2340 rpm is obtained on tacho-

m e t e r.

T e l l a s s i s t a n t t o d e p r e s s a c c e l e r a t or

pedal as far as it will go.

Tachometer should indicate 2300 to

2340 rpm.

T e l l a s s i s t a n t t o i d l e e n g i n e f or

three minutes then shut off engine.

Tachometer indication at idle

speed should be 700 to 750 rpm;

tachometer indication with ac-

celerator pedal completely de-

pressed should be 2300 to 2340

rpm.

a. If engine rpm is not as specified above, check adjustment of ac-

c e l e r a t o r l i n k a g e ( p a g e 4 - 6 4 ) ; a d j u s t i f n e c e s s a r y . I f a d j u s t -

ment is okay, notify next higher maintenance level to adjust

fuel injection pump.

b. If engine rpm is as specified above, go to step 8 below.

Park loader on level surface and apply parking brake valve by pull-

ing knob outward.

Put transport/service link in engaged position to prevent turning of

loader (page 9-8).

B e f o r e p e r f o r m i n g f o l l o w i n g s t e p s , b e s u r e t h a t t r a n s p o r t / s e r v i c e l i nk

is engaged. Failure to do so could cause serious injury or death due to

chassis pivoting and crushing you when you are working in area between

front and r e a r c h a s s i s,

C h e c k t r a n s m i s s i o n o i l l e v e l , e n g i n e o i l l e v e l , a n d h y d r a u l i c s y s t em

oil level (refer to LO 5-3805-262-12). Add oil as necessary.

3-27