TM 5-3805-262-34

3-12. AIR BRAKE SYSTEM MAINTENANCE (CONT)

b. Service Brake Treadle and Valve and Declutch Treadle and Valve (Cont).

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Hand hammer, 16 ounces

Safety glasses

Snap ring pliers

Socket wrench set, 3/8 inch drive

No. 2 Common Organizational Maintenance Tool Kit

Torque wrench, 3/8 inch drive, 200 lb-in. capacity

Automotive Mechanic’s Tool Kit

Drive pin punch, 1/8 inch point

Screwdriver

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

Silicone lubricant (Appendix C, item 18)

Retaining compound (Appendix C, item 31)

Valve repair kit (FSCM 06853 PN 276119)

REFERENCE: TM 5-3805-262-20

NOTE

PRELIMINARY PROCEDURE: Service brake treadle and valve and declutch

treadle and valve removed from loader (refer to TM 5-3805-262-20).

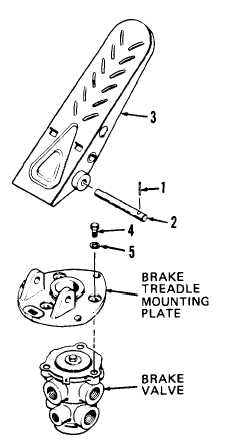

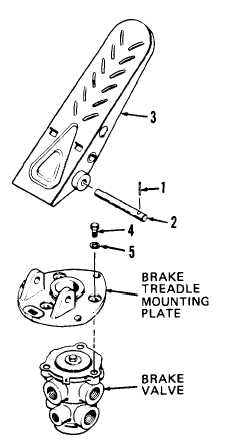

DISASSEMBLY INTO SECTIONS

(1)

Using drive pin punch and hammer,

remove roll pin (1) from fulcrum

pin (2).

(2)

Remove fulcrum pin (2) using drive

pin punch and hammer if necessary.

(3) Remove brake treadle (3) from

mounting plate.

(4)

Loosen and remove three capscrews

(4) and lock washers (5).

(5)

Separate brake treadle plate and

assembled parts from brake valve.

LEGEND

1. Roll pin

2, Fulcrum pin

3. Brake treadle

4. Capscrews (3)

5. Lock washers (3)

3-441