TM 5-3805-290-10

DESCRIPTION AND USE OF OPERATOR CONTROLS AND INDICATORS - CONTINUED

0004 00

LOADER AND AUXILIARY HYDRAULIC CONTROLS - CONTINUED

0004 00

2.

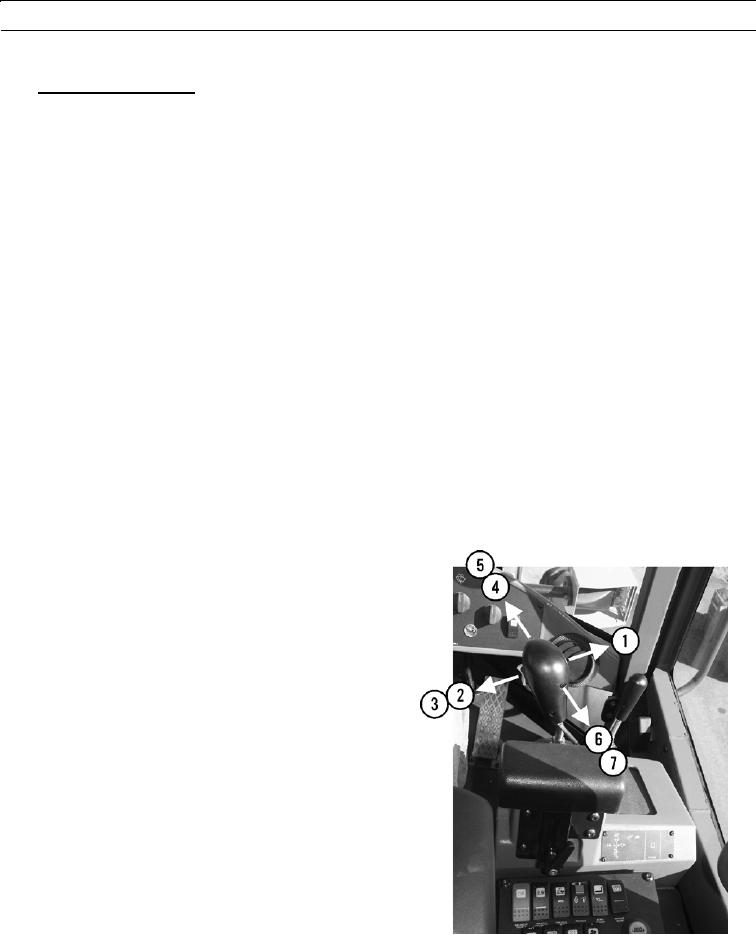

Loader Control Joystick.

a.

DUMP (1). Move joystick to the right to tilt loader arm (bucket or forks) forward. Release joystick to stop move-

ment. Joystick will return to HOLD position when released.

b.

TILT BACK (2). Move joystick the left to tilt loader arm backward, i.e., to "rack" the bucket or forks. Release

joystick to stop movement. Joystick will return to HOLD position when released.

c.

TILT KICKOUT (3). Move joystick all the way left into detented TILT KICKOUT position. Joystick will remain

in detent and loader arm will continue to tilt back, until loader arm reaches preset location for tilt (return to work/

return to dig) kickout. Then, joystick will return to center HOLD position.

d.

LOWER (4). Move joystick forward to lower loader arm. Release joystick to stop movement. Joystick will return

to HOLD position when released.

CAU T I ON

NEVER use RETURN TO CARRY position when loader arm is loaded. Machine damage may result.

e.

RETURN TO CARRY (5).

(1)

Move joystick all the way forward into detent. Loader arm will raise until it reaches proper height to carry

load.

(2)

Joystick will remain in RETURN TO CARRY until it is pulled out of detent, at which point it will return to

HOLD.

f.

RAISE (6). Move joystick back to raise loader

arm. Release joystick to stop movement. Joystick

will return to HOLD position when released.

g.

LIFT KICKOUT (7). When joystick is pulled

all the way back to detented LIFT KICKOUT

position, joystick will remain in detent and

loader arm will continue to rise until it reaches

lift kickout height. Then, joystick will return to

HOLD position.

h.

HOLD. Joystick will return to center HOLD

position when released. Loader arm will remain

in selected position.

427-B0103F

0004 00-25