TM 5-3805-290-10

ENGINE AIR PRECLEANER AND AIR CLEANER SERVICE - CONTINUED

0014 00

ENGINE AIR CLEANER SERVICE - CONTINUED

6.

Clean inside of air cleaner housing with rag.

7.

Inspect seal on secondary filter element. If damaged, obtain replacement from Unit Maintenance.

CAU T I ON

DO NOT use a damaged primary filter element. Engine damage can result.

8.

Inspect primary filter element for damaged pleats, tears, holes, gaskets, and seals. Discard primary filter element if any

damage is evident. Obtain replacement from Unit Maintenance.

9.

If primary filter element is serviceable, clean as follows:

WARN I N G

Particles blown by compressed air are hazardous. Use a maximum of 30 psi (207 kPa) when cleaning com-

ponents. DO NOT direct compressed air against human skin. Make sure air stream is directed away from

user and other personnel in the area. To prevent injury, user must wear protective goggles or face shield.

Failure to follow this warning may result in injury or death to personnel.

CAU T I ON

To prevent damage, DO NOT clean primary filter element by bumping or tapping.

DO NOT wash primary filter element.

a.

Direct compressed air inside primary filter element, from top to bottom along length of filter pleats.

b.

Direct compressed air outside primary filter element, from top to bottom along length of filter pleats.

N OT E

A light may be used to inspect for damage inside primary filter element.

10.

After cleaning, inspect primary filter element again for damaged pleats, tears, holes, gaskets, and seals. Discard primary

filter element if any damage is evident. Obtain replacement from Unit Maintenance.

11.

Remove rag.

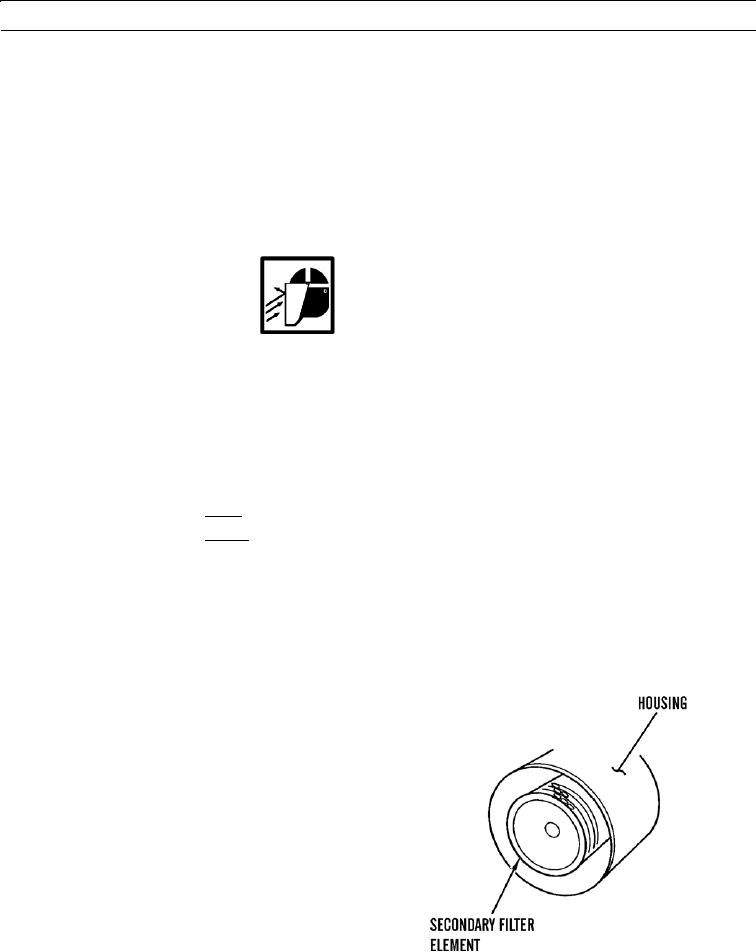

N OT E

Secondary filter element must be replaced with

every third primary filter element replacement.

12.

Uncover air inlet opening and install secondary filter

element inside air cleaner housing.

427-B0566

0014 00-4