TM 5-3805-290-23-1

THEORY OF OPERATION - CONTINUED

0003 00

FUEL SYSTEM - CONTINUED

a.

Delivery.

(1)

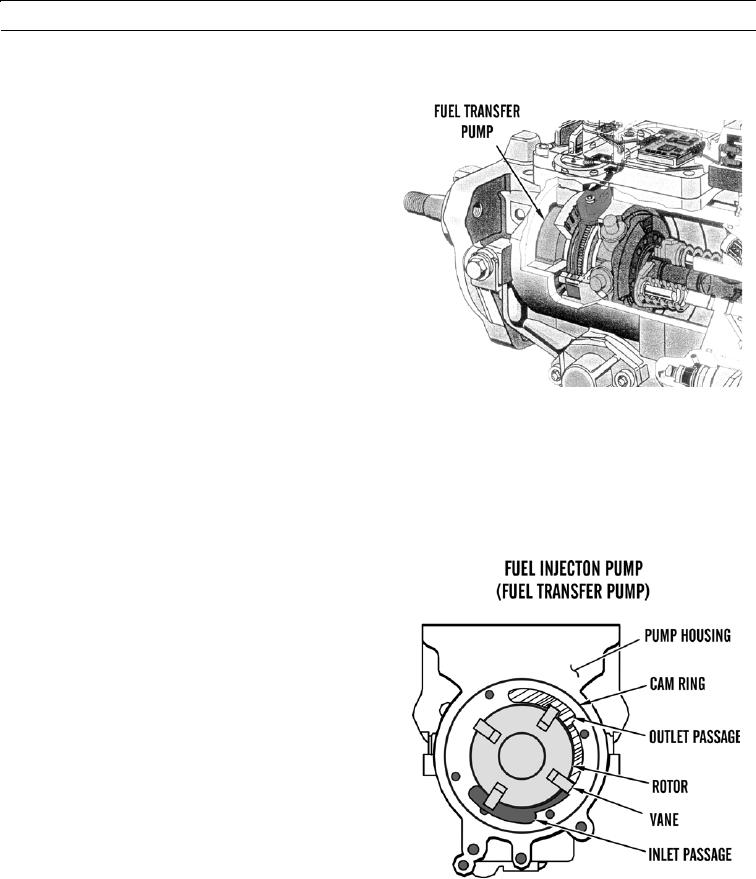

Fuel is supplied by priming pump. Fuel

enters transfer pump of fuel injection

pump. Fuel transfer pump is a vane type

pump driven by fuel injection pump

shaft. Pump supplies a constant amount

of fuel to interior of fuel injection pump.

Revolution of transfer pump is directly

related to speed of fuel injection pump

shaft.

427-B1507

(2)

Rotor rotates inside cam ring. Cam ring is firmly attached to pump housing. Vanes are pressed against cam

ring by centrifugal force. Fuel flows through an inlet passage into recess in pump housing.

(3)

Eccentric position of rotor is relative to cam ring. A volume is created between: vanes, rotor, and cam ring.

Fuel is transported by eccentric position relative to rotor and outlet passage. Fuel is transferred through

outlet passage into distributor plunger. Volume of fuel is reduced between inlet passage and outlet passage.

This creates pressure before delivery to distributor plunger.

(4)

Fuel quantity increases as speed of

engine increases. Increased engine speed

increases fuel delivery pressure. Pressure

inside fuel injection pump is limited by

pressure regulator. Pressure regulator

controls fuel pressure. Fuel forces valve

spring open and flows back into inlet

passage from inside of fuel injection

pump.

427-B1516

0003 00-8