TM 5-3805-290-23-1

THEORY OF OPERATION - CONTINUED

0003 00

FUEL SYSTEM - CONTINUED

(1)

Injection pump ECU is mounted on top of pump. ECU has a connection to engine ECM and a connection

to speed/timing sensor. ECU has a connection for two solenoid valves. ECM functions as a control com-

puter. ECU calculates optimal parameters from ECM data. Fuel solenoid actuates valve accordingly.

(2)

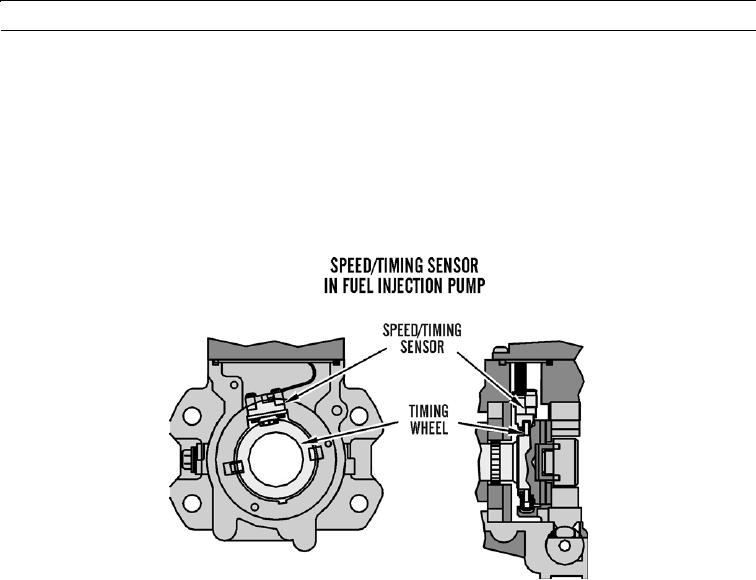

Speed/timing sensor in fuel injection pump determines precise angular position and speed of fuel injection

pump shaft. Timing wheel is permanently connected to fuel injection pump shaft. Speed/timing sensor gets

information from timing wheel. Sensor then sends electrical impulses to ECU. ECU also uses information

to determine average and momentary pump speed.

(3)

Speed/timing signal sensor is constant.

427-B1524

0003 00-13