TM 5-3805-290-23-1

THEORY OF OPERATION - CONTINUED

0003 00

TRANSMISSION - CONTINUED

17.

Transmission Power Flow.

a.

Machine ECM determines proper clutches to engage based on inputs, including machine speed, engine speed, and

operator inputs.

b.

When engine is started, transmission oil pump pulls oil from sump and sends it through transmission oil filter.

Pressurized transmission oil flows from transmission oil filter to oil inlet in transmission housing, then through an

internal passage in transmission housing. Oil then flows through transmission relief valve into modulating valves.

c.

Oil in clutches that are not engaged is sent back to sump as return oil.

d.

Transmission relief valve controls pressure of pump oil supplied to modulating valves. Transmission relief valve

directs unneeded pump oil to torque converter as torque converter oil. Torque converter outlet oil flows through

torque converter outlet relief valve to oil cooler as lubrication oil. After oil cools, it flows through lubrication sys-

tem and to sump.

e.

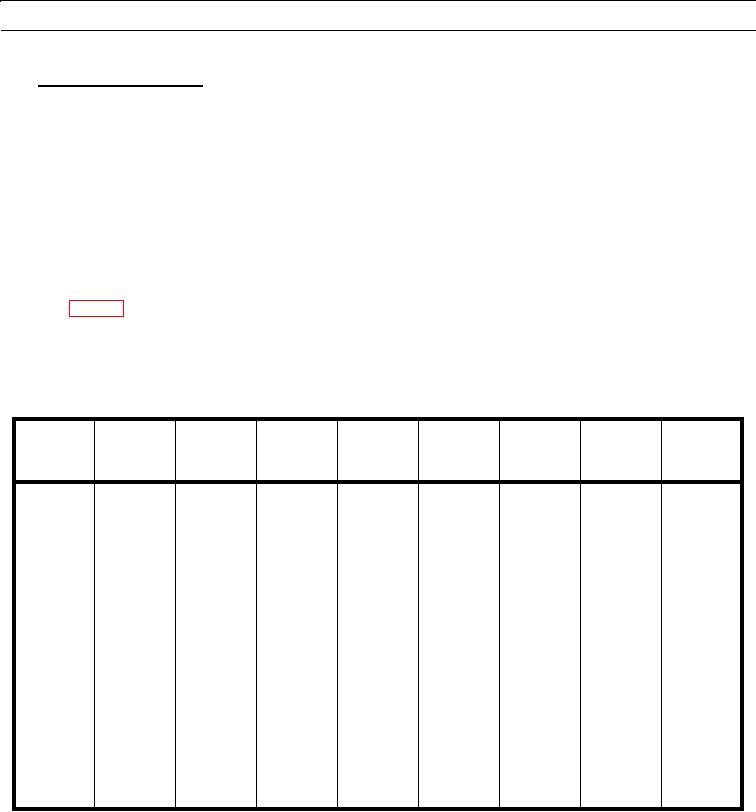

Table 3 gives clutch combinations that are engaged for each forward and reverse speed. There is a modulating

valve for each clutch which directs pressurized oil to clutch to engage it. A solenoid is located on each modulating

valve which controls modulating valve spool. Machine ECM controls solenoids.

Table 3. Transmission Clutch Combination.

Third

Second

Fourth

Third

Second

Speed

Speed

Speed

First Speed

Speed

Speed

First Speed

Reverse

Reverse

Forward

Neutral

Reverse

Forward

Forward

Forward

Clutch 1

X

X

X

(forward

low)

X

Clutch 2

(forward

high)

Clutch 3

X

X

X

(reverse)

X

Clutch 4

(second

speed)

Clutch 5

X

X

X

X

(third speed

and fourth

speed)

Clutch 6

X

X

(first speed)

0003 00-60