TM 5-3805-290-23-1

ELECTRICAL SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0013 00

CAT DATA LINK CIRCUIT TEST - CONTINUED

b.

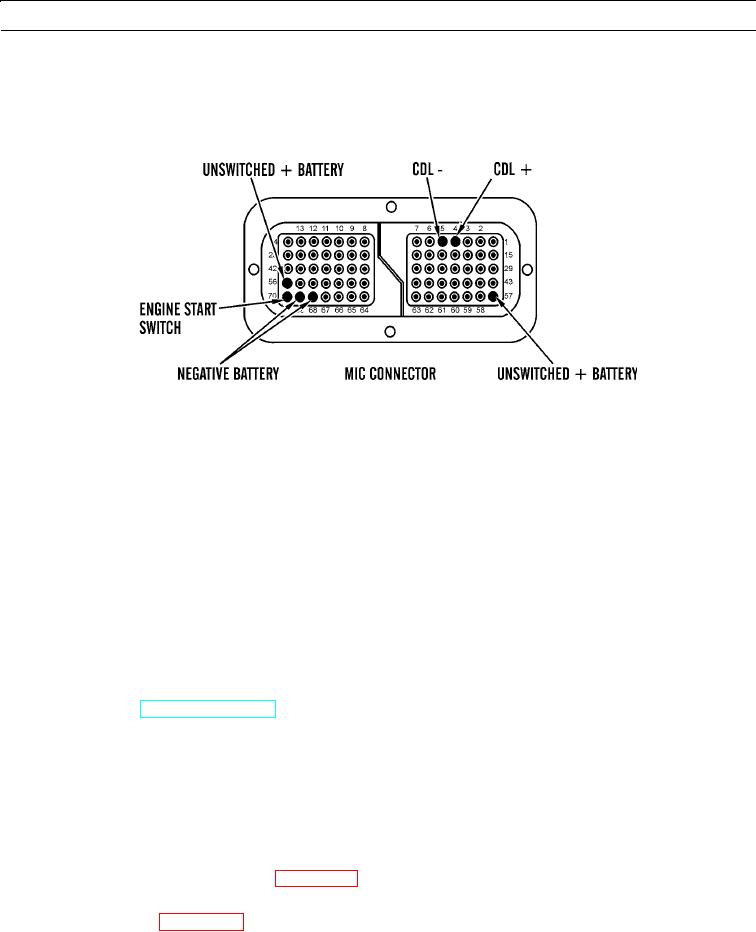

Data link connectors J80 and J20/P20 (WP 0053 00 and WP 0170 00).

c.

J20 customer connector (pin 4 and pin 5).

427-B0680

d.

MSD and CAT communication adapter connectors.

e.

CAT data link (terminal 4 and terminal 5) in J1/P1 ECM connector (WP 0053 00).

f.

Perform 10 lb (45 N) pull test on each wire in ECM connector that is associated with CAT data link.

g.

Check ECM connector (socket-head screw) for proper torque of 55 lb-in. (6 Nm).

h.

Check harness and wiring for abrasion and pinch points from connector to ECM.

i.

Expected Results. All connectors, pins, and sockets are completely connected and/or inserted and harness and wir-

ing are free of corrosion, abrasion, or pinch points.

(1)

If results are OK, reconnect all connectors and proceed to step 2.

(2)

If results are NOT OK, replace wiring harness in question (WP 0169 00 thru WP 0175 00). Ensure all seals

are properly in place and that connectors are completely connected. Verify repair eliminates problem.

2.

Determine type of problem.

a.

Connect MSD to J80 diagnostic connector.

b.

Start engine (TM 5-3805-290-10).

c.

Expected Results.

(1)

Engine starts. MSD powers up and communicates without error.

(a) There is no problem with CAT data link at this time.

(b) If intermittent condition exists, perform Electrical Connectors Inspection (WP 0022 00).

(2)

Engine starts. MSD powers up but error is displayed. ECM is receiving battery power. Proceed to step 3.

(3)

Engine cranks but will not start regardless of condition of MSD. Perform engine troubleshooting, Engine

Cranks but Will Not Start (WP 0008 00).

(4)

Engine will not crank regardless of condition of MSD. Perform engine troubleshooting, Engine Will Not

Crank (WP 0008 00).

(5)

Engine starts, but MSD does not power up. Ensure ECM is receiving correct battery power. Proceed to

step 4.

0013 00-15