TM 5-3805-290-23-1

ELECTRICAL SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0013 00

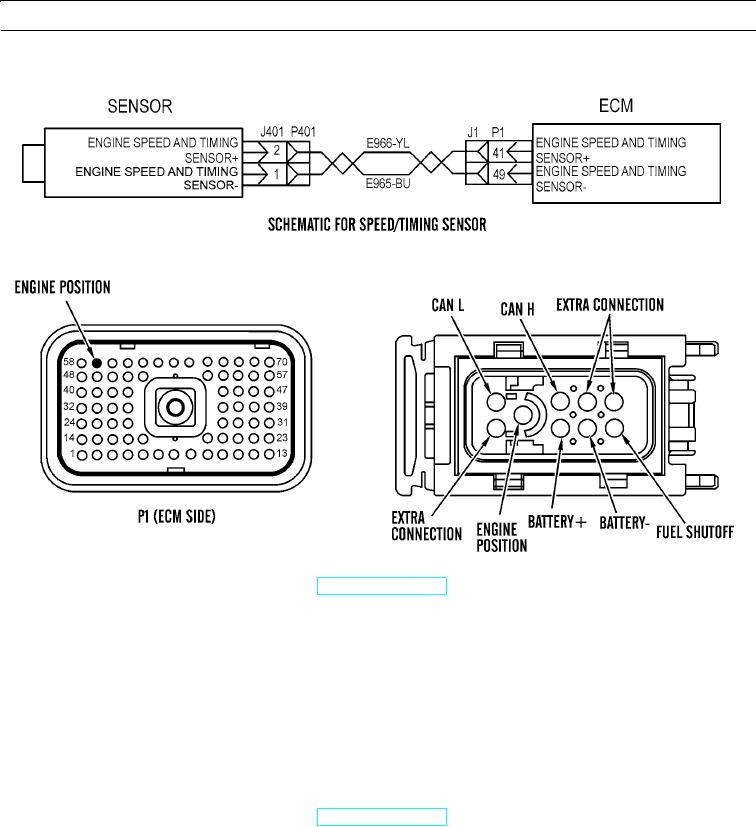

ENGINE SPEED/TIMING SENSOR CIRCUIT TEST - CONTINUED

427-B0710

427-B0713

427-B1537

a.

Turn engine start switch to OFF position (TM 5-3805-290-10).

b.

Disconnect P1 ECM connector and P40 fuel injection pump connector (WP 0053 00 and WP 0164 00).

c.

Measure resistance from terminal 59 engine speed/timing sensor at ECM to terminal 8 engine speed/timing sensor

of P40 fuel injection pump connector. Resistance should be less than 2 Ohms.

d.

Reconnect all connectors.

e.

Expected Results. Readings agree with values listed in step c.

(1)

If results are OK, ECM does not operate properly. Perform this repair on suspect ECM:

Replace engine ECM (WP 0053 00). Verify repair eliminates problem.

(2)

If results are NOT OK, readings are higher than 2 Ohms. Proceed to step 6.

6.

Check continuity of cables from ECM to fuel injection pump.

a.

Turn engine start switch to OFF position (TM 5-3805-290-10).

b.

Disconnect J1/P1ECM connector and J40/P40 fuel injection pump connector (WP 0053 00 and WP 0164 00).

0013 00-44