TM 5-3805-290-23-2

ELECTRICAL GENERAL MAINTENANCE INSTRUCTIONS - CONTINUED

0022 00

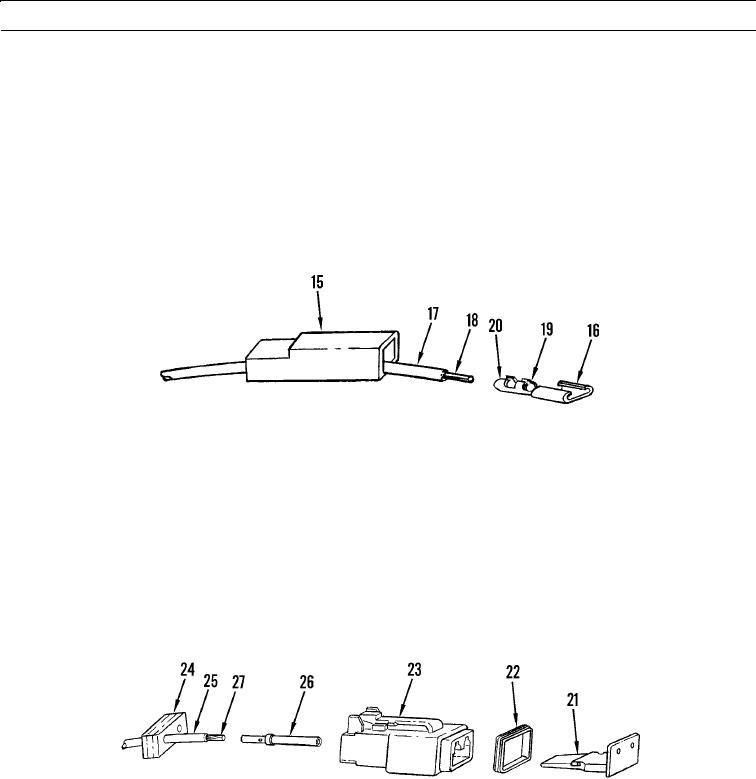

RECEPTACLE CONNECTOR REPAIR

0022 00

1.

Using removal tool, insert tool into front of connector (15) and depress locking tab of receptacle (16).

2.

Push wire (17), with receptacle (16) attached, through front of connector (15).

3.

If defective, remove receptacle (16) from wire (17) by cutting through wire just behind receptacle.

N OT E

Perform steps 4 thru 7 only if receptacle was removed.

4.

Slide connector (15) back on wire (17).

427-B1923

5.

Using wire stripping tool, strip insulation from wire (17) to expose 1/4-in. (6 mm) length of metal strands (18).

6.

Using crimping tool, securely crimp tabs (19) of receptacle (16) over metal strands (18).

7.

Using crimping tool, crimp tabs (20) of receptacle (16) over insulation of wire (17).

8.

Slide connector (15) forward over receptacle (16) until receptacle locking tab snaps into place.

0022 00

WATERPROOF CONNECTOR REPAIR

1.

Remove end cover (21) and gasket (22) from front of connector (23).

2.

Remove seal (24) from rear of connector (23) and slide seal back on wire (25).

427-B1924

N OT E

Perform the following steps for each wire of connector.

Tag wires to aid in installation.

3.

Using pin removal tool, insert tool into front of connector (23) and depress locking tab of connector.

4.

Remove wire (25) with pin (26) from rear of connector (23).

5.

If defective, remove pin (26) from wire (25) by cutting through wire just behind pin.

0022 00-6