TM 5-3805-290-23-2

HYDRAULIC SYSTEM OIL CHANGE AND FILTER REPLACEMENT - CONTINUED

0137 00

DRAINING

N OT E

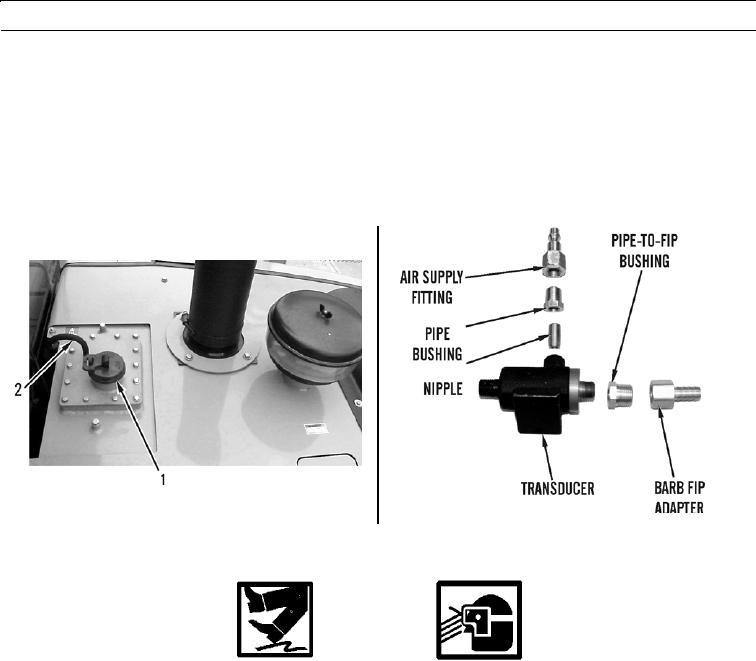

Remove hydraulic tank filler cap (1) to speed draining.

1.

Install nipple, pipe bushing, and air supply fitting on top of vacuum transducer.

2.

Install pipe-to-FIP bushing and barb FIP adapter on vacuum transducer.

3.

Place transducer assembly in vent tube (2) and connect shop air to apply continuous vacuum.

427-B0216

427-B2012

WARN I N G

Lubricating/hydraulic oils used in the performance of maintenance can be very slippery. Immediately wipe up

any spills. Failure to follow this warning may result in injury to personnel.

To prevent injury to personnel, wear protective eye covering and gloves.

When servicing this machine, performing maintenance, or disposing of hazardous materials, consult your

unit/local hazardous waste disposal center or safety office for local regulatory guidance. If further informa-

tion is needed, please contact The Army Environmental Hotline at 1-800-872-3845.

CAU T I ON

Wipe area clean around all connections to be opened during removal. Cap lines and hoses and plug open-

ings after removing lines. Contamination of system could result in premature failure.

N OT E

Use a container to catch any fluid that may drain from hoses or system. Dispose of fluid IAW local policy and

ordinances. Ensure all spills are cleaned up.

Hydraulic tank capacity is approximately 18.5 gal. (70 L).

0137 00-2