TM 5-3805-290-23-2

ENGINE WIRING HARNESS REPLACEMENT - CONTINUED

0170 00

INSTALLATION - CONTINUED

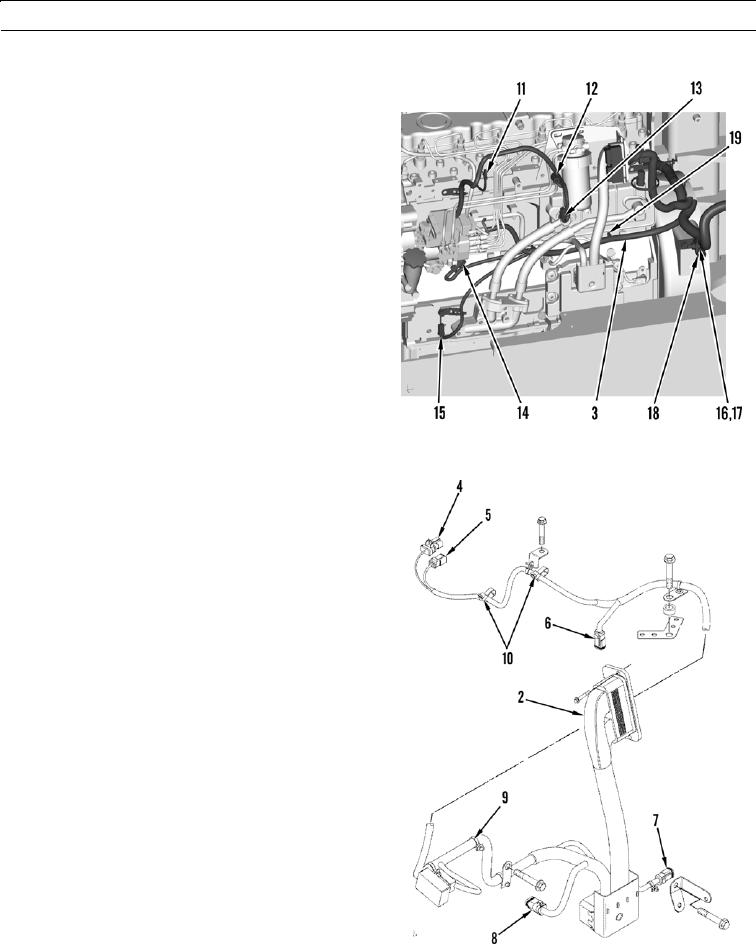

11.

From right side of machine, install nine new tiedown

straps (19) on wiring harness (3).

12.

Install clamp (18) on wiring harness (3).

13.

Install washer (17) and bolt (16) on clamp (18).

14.

Connect wiring harness (3) to gear pump pressure sen-

sor (15).

15.

Connect wiring harness (3) to fuel injection pump sen-

sor (14).

16.

Connect wiring harness (3) to ether starting aid sole-

noid (13).

17.

Connect wiring harness (3) to fuel filter solenoid (12).

18.

Connect wiring harness (3) to air cleaner indicator

sensor (11).

427-B1005

19.

Position wiring harness (2) on machine.

20.

Install six clips (10) on machine.

21.

Install two new tiedown straps (9) on wiring harness

(2).

22.

Connect wiring harness (2) to engine oil pressure sen-

sor (8).

23.

Connect wiring harness (2) to speed/timing sensor (7).

24.

Connect wiring harness (2) to coolant temperature

sensor (6).

25.

Connect wiring harness (2) to inlet air temperature

sensor (5).

26.

Connect wiring harness (2) to atmospheric pressure

sensor (4).

427-B1004

0170 00-6