TM 5-3805-291-10

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

INCLUDING LUBRICATION INSTRUCTIONS - CONTINUED

0012 00

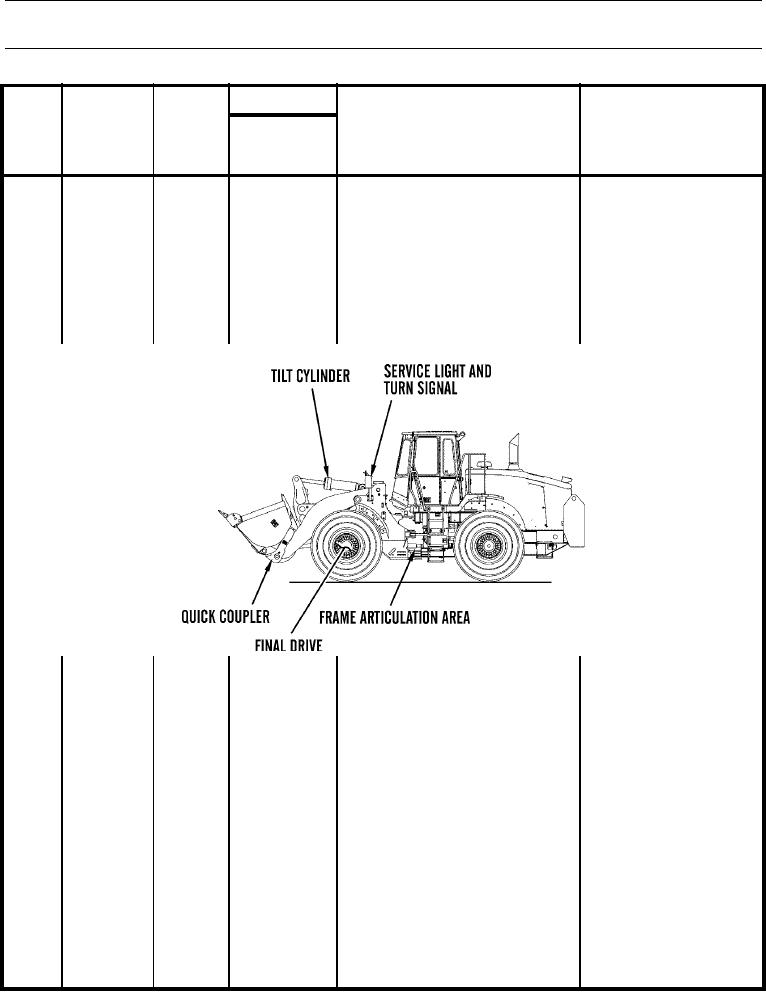

Table 1. Preventive Maintenance Checks and Services (PMCS) for the 966H Wheel Loader - Continued.

LOCATION

ITEM TO

CHECK/

ITEM

MAN-

NOT FULLY MISSION

SERVICE

NO.

INTERVAL

HOURS

PROCEDURE

CAPABLE IF:

a. Check for missing bolts.

Two or more bolts are miss-

6

Before

Left-Front

ing.

Wheel and

Tire

b. Check tread and sidewall for cuts Damage to tire that would

lead to tire failure is evident.

and foreign material in treads.

c. Visually check tire inflation.

Tire is flat.

d. Check back side of wheel for oil Class III oil leaks are evi-

dent.

leaks from final drive.

a. Check that left-front service light Lights are missing or dam-

7

Before

Left-Front

assembly (service lights and turn- aged7-Cif 64required for mis-

42, 00

Lights

lamps) is present and not dam- sion.

aged.

b. Check that blackout drive light is Blackout drive light is miss-

ing or damaged, if required

present and not damaged.

for mission.

a. Check for cracks or breaks in drive Cracks or breaks are evi-

8

Before

Frame Articu-

dent.

lation Area

shaft.

b. Inspect hydraulic hoses for dam- If cracks, splits, bulges, or

soft spots are evident in

age or leaks.

hoses, or Class III leaks are

evident.

c. Inspect for missing, damaged, or

leaking remote grease fittings.

0012 00-3