TM 5-3805-291-10

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

INCLUDING LUBRICATION INSTRUCTIONS - CONTINUED

0012 00

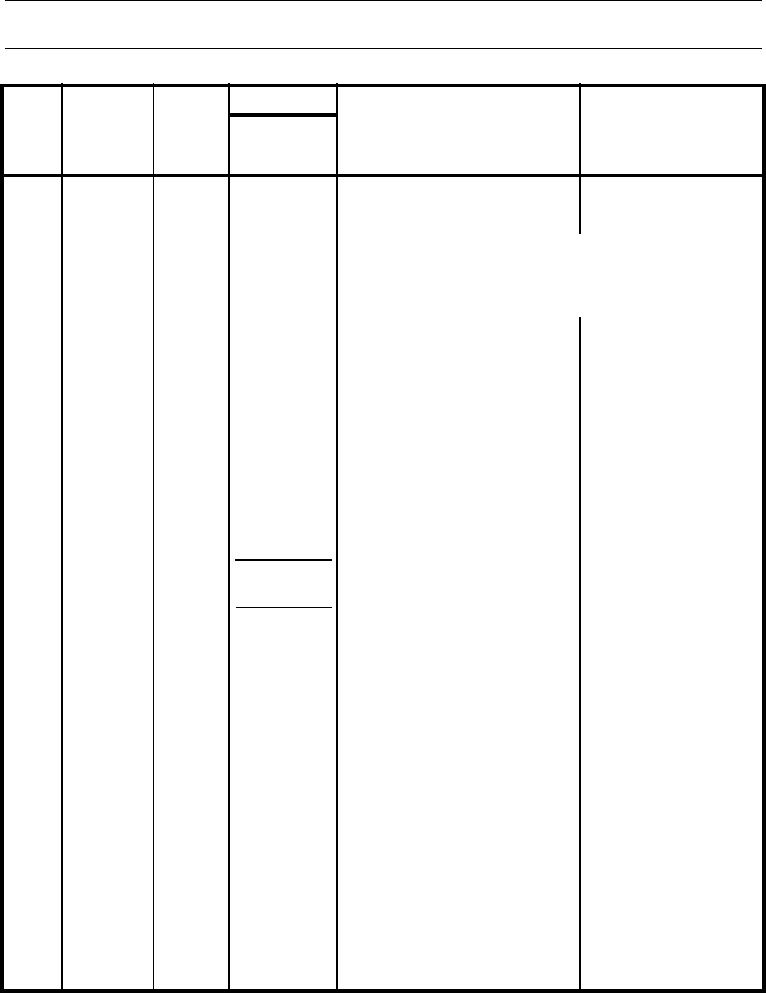

Table 1. Preventive Maintenance Checks and Services (PMCS) for the 966H Wheel Loader - Continued.

LOCATION

ITEM TO

ITEM

MAN-

NOT FULLY MISSION

CHECK/

SERVICE

NO.

INTERVAL

HOURS

PROCEDURE

CAPABLE IF:

e. Check back side of wheel for oil Class III oil leaks are evi-

48

After

Left-Rear

leaks from final drive.

dent.

Wheel and

(Con't)

Tire

CAU T I ON

49

After

Left-Side

Engine Enclo-

Screen prevents stones or other flying debris from entering

sure

engine compartment and causing damage to oil coolers and

radiator. Ensure screen is maintained in good condition.

a. Inspect left-side access door for

damage. Remove any foreign

material from screen.

b. Check for debris and damage to Damage is evident. If

hoses, tubes, and wires/connectors cracks, splits, bulges, or soft

in left-side engine enclosure. spots are evident in hoses.

Remove any debris found.

c. Check for evidence of leaks.

Class III leaks are evident.

Any fuel leakage is evident.

d. Inspect around turbocharger and Exhaust leaks are evident.

exhaust manifold for exhaust

leaks.

REAR AND

RIGHT SIDE

a. Check on ground under machine Class III oil or coolant leaks

50

After

Overall View

for evidence of fluid leakage such are evident. Any fuel leaks

as oil, coolant, or fuel.

are evident.

b. Check machine for obvious dam- Damage that would impair

age that would impair operation.

operation is evident.

a. Check that rear lights are present Rear lights are missing or

51

After

Rear of

and not damaged.

damaged, if required for

Machine

mission.

b. Open rear access door.

c. Ensure fuel tank filler cap is Fuel tank filler cap is miss-

installed.

ing.

d. Check for evidence of any leak.

Any fuel leaks are evident.

0012 00-26