TM 5-3805-291-23-1

THEORY OF OPERATION - CONTINUED

0003 00

ENGINE - CONTINUED

b.

Turbocharger.

(1)

Turbocharger produces boost across entire engine rpm range. Increased boost at low rpm fills combustion

chamber with dense air. Dense air mixes with fuel to promote a complete combustion.

(2)

Turbocharger has a compressor wheel and a turbine wheel, both connected to a common shaft supported

by two bearings. Bearings are lubricated by pressurized engine oil which enters through oil inlet port.

Engine oil lubricates bearings and removes heat. Oil returns to oil sump through oil outlet port.

427-C1720

c.

Cylinder Head.

Cylinder head houses all valves and is ported to allow for cooling, air intake, and lubrication.

d.

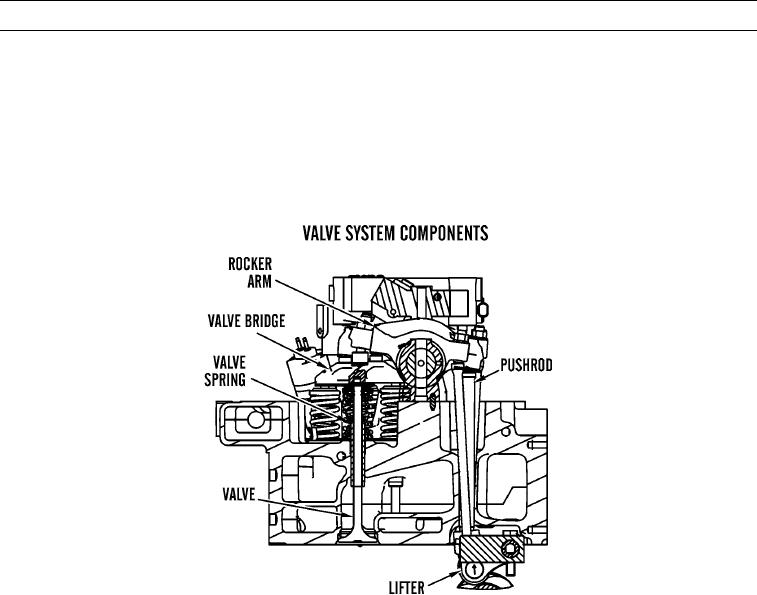

Valve System Components.

(1)

Valve system components control inlet air flow into and out of cylinders during engine operation. Valve

mechanism also operates fuel injector.

(2)

Camshaft must be timed to crankshaft to get correct relation between piston movement and valve move-

ment.

(3)

Camshaft has three camshaft lobes for each cylinder. Lobes operate fuel injectors, inlet valves, and exhaust

valves. As camshaft turns, camshaft lobes cause lifters to move pushrods up and down. Upward pushrod

movement against rocker arms results in downward movement (opening) of valves.

(4)

Each cylinder has two inlet and exhaust valves. Valves are actuated simultaneously by a valve bridge.

Valve springs close valves when lifters move down.

e.

Exhaust Manifold.

(1)

Exhaust manifold channels engine exhaust through wastegate valve.

(2)

Wastegate valve in turbocharger directs engine exhaust through turbocharger or allows exhaust to bypass

turbocharger when boost pressure reaches maximum.

0003 00-11