TM 5-3805-291-23-1

THEORY OF OPERATION - CONTINUED

0003 00

STEERING SYSTEM - CONTINUED

(1)

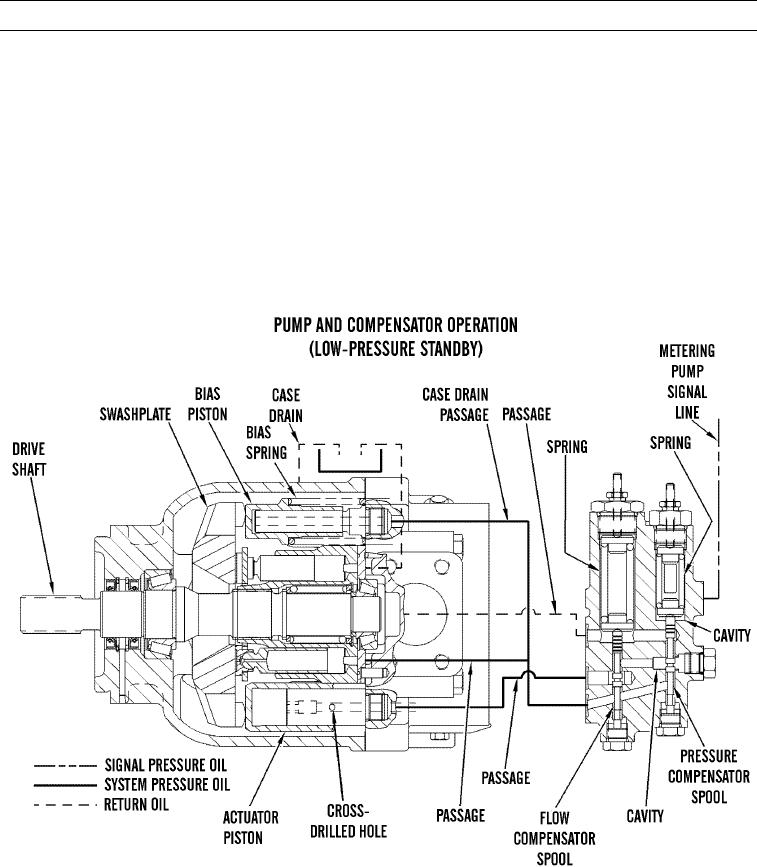

Decreased flow demand causes a signal pressure in metering pump signal line. Signal pressure in line

combines with force of spring in pressure compensator cavity. This combined force is less than pump pres-

sure in passage, causing pressure compensator spool to move upward.

(2)

Oil behind actuator piston cannot flow through passage to case drain. Pump oil now flows through passage

to pressure compensator spool, then past spool, through passage, and to actuator piston.

(3)

Pump pressure behind actuator piston is now greater than combined force of bias piston and bias spring.

Swashplate angle decreases, decreasing pump output and system pressure.

(4)

When lower flow requirements are met, flow compensator spool moves down to metering position.

Swashplate maintains an angle sufficient to provide lower required pressure. If operator does not turn

steering wheel, pump will return to low-pressure standby.

l.

Low-Pressure Standby.

427-C1789

0003 00-113