TM 5-3805-291-23-1

THEORY OF OPERATION - CONTINUED

0003 00

ELECTRO-HYDRAULIC SYSTEM - CONTINUED

427-C1810

n.

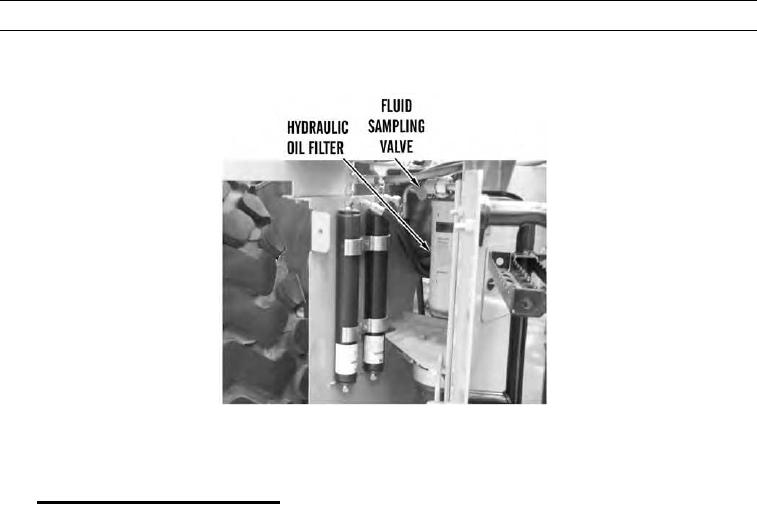

Hydraulic oil filter is located on right side of machine behind service door. Sampling valve is located on hydraulic

oil filter. Hydraulic oil filter is in return line from hydraulic fan system. Fluid sampling valve is located above

hydraulic oil filter, and is available to check hydraulic oil quality.

2.

Implement Electronic Control System.

a.

Implement ECM monitors position of joystick position sensors located in operator compartment. When joystick is

moved, implement ECM detects amount of position sensor movement, then activates corresponding solenoid

valve. Implement ECM activates solenoid valve in proper amount to move work tool at appropriate speed.

b.

Implement ECM electronically controls pilot proportioning solenoid valves, then solenoid valves control move-

ment of stems in main control valve for work tool and any auxiliary hydraulic attachments. Position sensors detect

movement in joystick and sensors will develop a signal. Implement ECM reads signals and activates appropriate

pilot proportioning solenoid valve. As a position sensor begins to rotate, implement ECM sends a small amount of

current to solenoid valve to move cylinder. As rotation of position sensor begins to increase, implement ECM

increases amount of current to solenoid valve. Speed of cylinder increases proportionally in response.

c.

Hydraulic lockout solenoid valve is activated by implement ECM whenever engine is running. Hydraulic lockout

solenoid valve is an ON/OFF valve that controls pilot oil flow through oil manifold pilot valve. If hydraulic lock-

out switch is in LOCKED position, implement ECM will not supply current to hydraulic lockout solenoid valve.

0003 00-140