TM 5-3805-291-23-1

HOW TO USE MSD WITH ET - CONTINUED

0005 00

STATUS GROUPS - CONTINUED

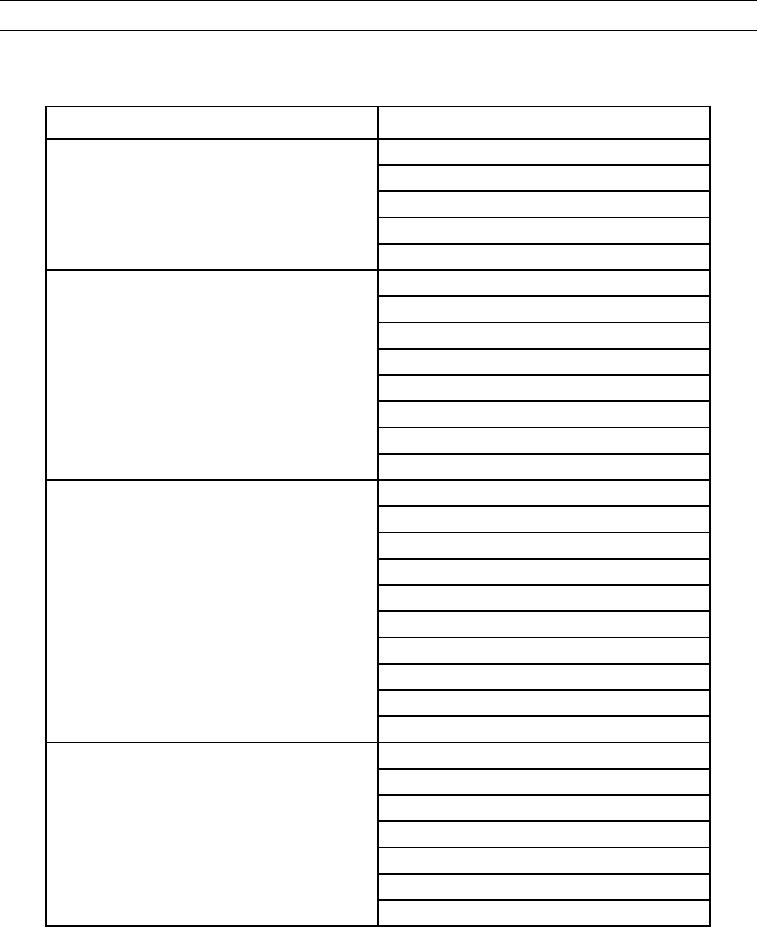

Table 4. Implement ECM - Continued.

Status Screen

Parameters

Screen 4 (3rd Function) - Continued

3rd Function Forward Solenoid Command

Continuous Flow Switch

Continuous Flow

Implement Pilot Supply Solenoid

Implement Lockout Switch Position

Screen 5 (Autodig Input/Output)

Lift Cylinder Head Pressure

Autodig Operation Mode Switch Status

Autodig Mode Switch Position

Autodig Trigger Switch Status

Autodig Kickout Set Switch Status

Autodig Automatic Trigger Mode Indicator Status

Autodig Operator Trigger Mode Indicator Status

Autodig Record Mode Indicator Status

Screen 6 (Autodig System)

Lift Cylinder Head Pressure

Autodig Mode Switch Position

Autodig Trigger Switch Status

Raise Solenoid #1 Current Command

Lower Solenoid #1 Current Command

Rackback Solenoid #1 Current Command

Dump Solenoid #1 Current Command

Ground Speed/Direction **From: Transmission

Actual Gear **From: Transmission

Engine Speed **From: Engine

Screen 7 (Operator Input)

Implement Lockout Switch Position

Kickout Set Switch

Fine Modulation Mode Switch Position

Continuous Flow Switch

Lift Lever Position Sensor Duty Cycle

Tilt Lever Position Sensor Duty Cycle

3rd Lever Position Sensor Duty Cycle

0005 00-14