TM 5-3805-291-23-1

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

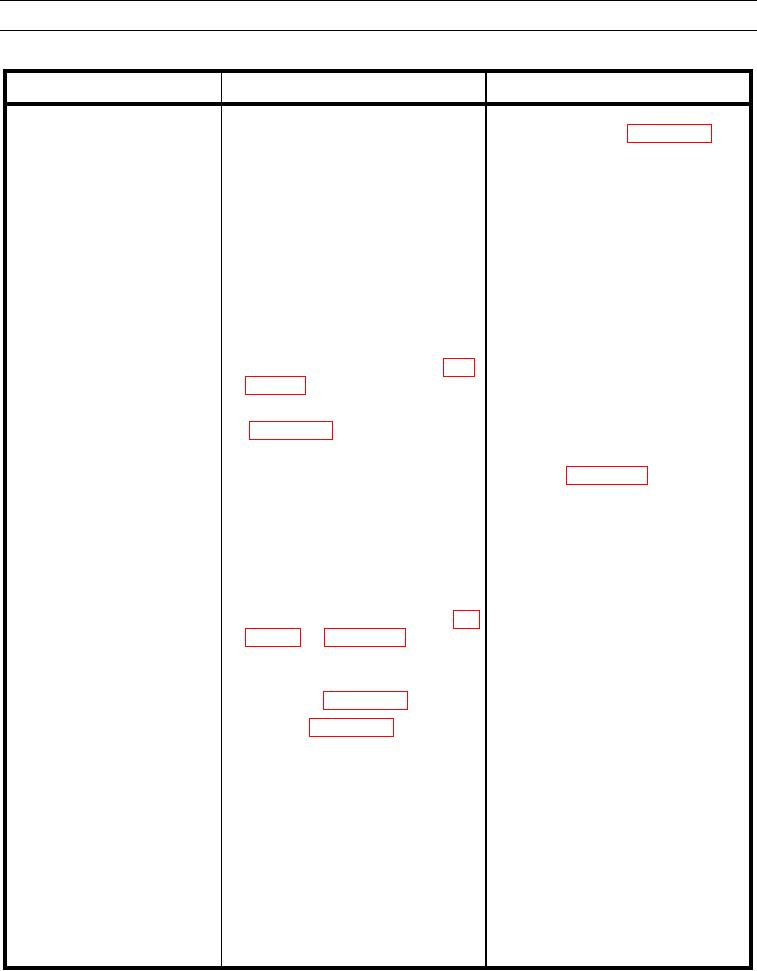

Table 1. Engine Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. Ensure all fuel lines are tight, properly

1. Replace, tighten, secure, or clean fuel

15. Poor Acceleration or

secured, and free of restrictions.

lines, as necessary (WP 0034 00).

Response - Continued.

2. If problem still exists, go to Test 4.

4. Check fuel tank for foreign objects.

1. Remove any foreign objects.

2. If problem still exists, go to Test 5.

5. Check to see if any of the following

1. If procedures have been performed,

procedures have been performed:

prime fuel system (TM 5-3805-291-

replacement of fuel filters, service on

10).

low pressure fuel supply circuit, or

2. If problem still exists, go to Test 6.

replacement of fuel injectors.

6. Perform Fuel Quality Test (WP 0011

If problem still exists, go to Test 7.

00).

7. Perform Air in Fuel System Test (WP

If problem still exists, go to Test 8.

8. Perform Fuel System Pressure Test

If problem still exists, go to Test 9.

9. If temperature is below 32F (0C),

1. If solidified fuel is present, drain and

check for solenoid fuel (wax) in tank.

fill tank (WP 0033 00).

2. If problem still exists, go to Test 10.

10. Observe the check engine lamp. Check 1. If restriction is indicated, clean or

air filter restriction indicator.

replace air cleaner elements (WP 0030

00).

2. If problem still exists, go to Test 11.

11. Check the air intake and exhaust

1. Remove any blockage or restrictions

system for restriction and/or leaks (WP

and replace damaged air inlet and

0031 00 and WP 0040 00).

exhaust system lines or hoses.

2. If problem still exists, go to Test 12.

12. Perform Electrical Power Supply

If problem still exists, go to Test 13.

Circuit Test (WP 0013 00).

13. Use MSD (WP 0005 00) to verify

1. If necessary, re-flash ECM (WP 0057

correct flash file is installed.

00).

2. If problem still exists, go to Test 14.

14. Use MSD to monitor the status of "Fuel 1. If "Fuel Position" equals "Rated Fuel

Position", "Rated Fuel Limit", and

Limit" and "Fuel Position" is less than

"FRC Fuel Limit" on ET while the

"FRC Fuel Limit", the ECM is

engine is operating under full load.

operating correctly.

These parameters should reflect the

2. If problem still exists, go to Test 15.

following information: "Fuel Position"

equals "Rated Fuel Limit" and "Fuel

Position" is less than "FRC Fuel

Limit."

0008 00-16