TM 5-3805-291-23-1

COOLING SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0012 00

COOLING SYSTEM INSPECTION - CONTINUED

N OT E

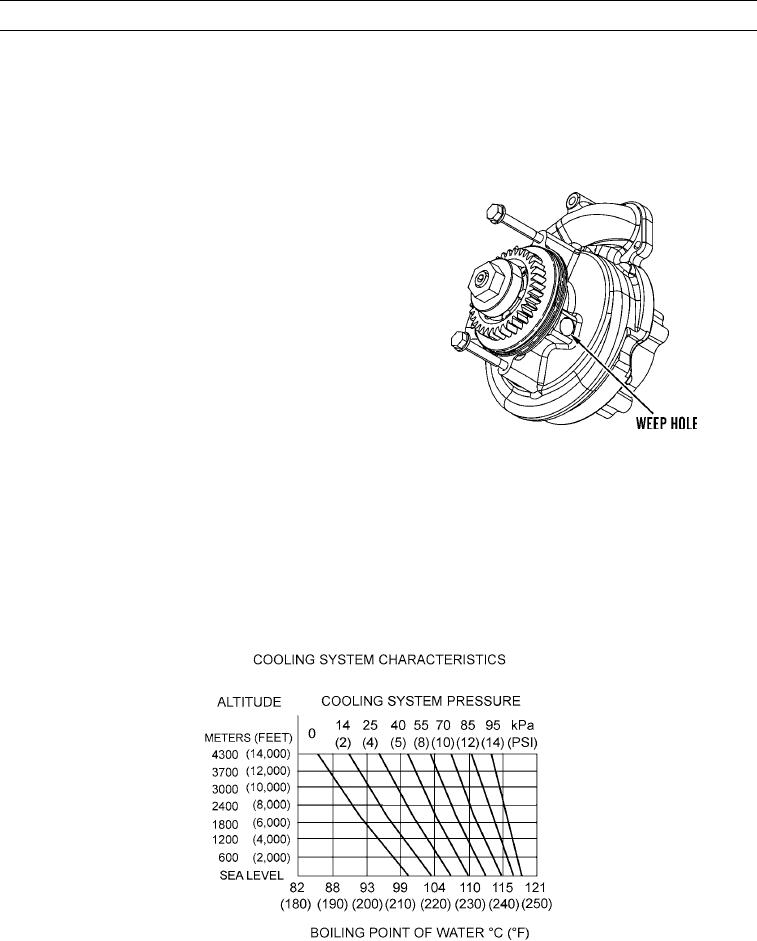

A small amount of coolant leakage across the surface of the water pump seals is normal. This leakage

is required to provide lubrication for this type of seal. A hole is provided in the water pump housing to

allow this coolant/seal lubricant to drain from the pump housing. Intermittent leakage of small

amounts of coolant from this hole does not indicate water pump seal failure.

3.

Look for leaks in cooling system.

4.

Inspect radiator for bent fins and other debris, restrict-

ing airflow through radiator.

5.

Inspect fan blades for damage.

6.

Look for air or combustion gases in cooling system.

7.

Inspect radiator filler cap for damage. Seal surface

must be clean.

8.

Inspect for loose or missing shrouds resulting in

reduced air flow for cooling.

427-C2016

0012 00

COOLING SYSTEM TEST

N OT E

This engine has a pressure type cooling system A pressure type cooling system has two advan-

.

tages. The cooling system can be operated in a safe manner at a temperature higher than the nor-

mal boiling point (steam) of water.

This type of system prevents cavitation in the water pump. Cavitaion is the forming of low pres-

t

sure bubbles in liquids that are caused by mechanical forces. A pressure type cooling system helps

to prevent pockets of air from forming.

427-C1978

0012 00-3