TM 5-3805-291-23-1

FUEL SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0011 00

AIR INLET AND EXHAUST SYSTEM INSPECTION - CONTINUED

Exhaust Restriction

WARN I N G

Hot engine components can cause injury from burns Before performing maintenance on engine, allow

.

engine and components to cool.

Making contact with a running engine can cause burnsfrom hot parts and can cause injury from rotat-

ing parts. When working on a running engine, avoid contact with hot parts and rotating parts.

N OT E

Back pressure is difference in pressure between ex aust pressure at outlet elbow and atmospheric air.

h

Test location can be anywhere along the exhaus piping after turbocharger but before muffler.

t

1.

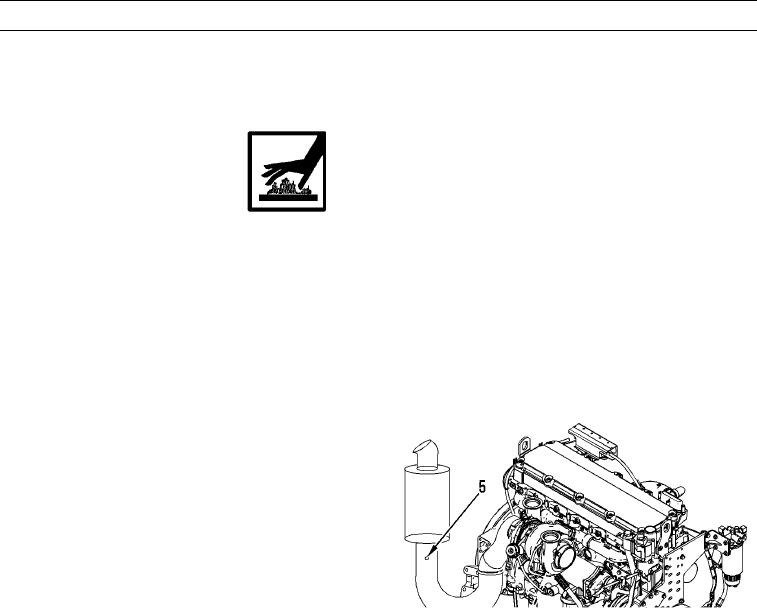

Connect differential pressure gage pressure port to test location (5).

2.

Leave differential pressure gage vacuum port open to

atmosphere.

3.

Start engine (TM 5-3805-291-10).

4.

Run engine in no-load condition at high idle (TM 5-

3805-291-10).

5.

Record value.

6.

Maximum allowed back pressure: 50 in. of H2O (12.4

kPa).

427-C0613

0011 00-11