TM 5-3805-291-23-1

AIR CONDITIONING SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0018 00

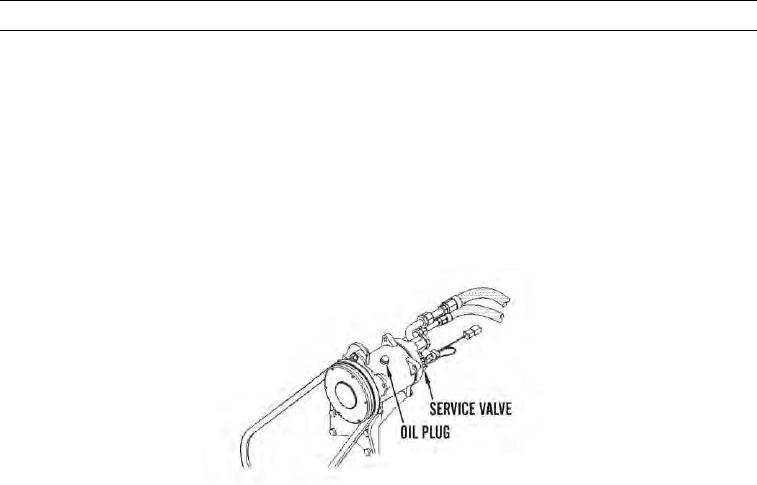

REFRIGERANT COMPRESSOR OIL CHECK - CONTINUED

Complete Check of Compressor Oil

1.

Operate engine at 1,000 rpm. Set temperature on maximum cooling setting. Move fan speed switch to HIGH. System

will stabilize in a minimum of 10 minutes (TM 5-3805-291-10).

2.

Stop engine. Remove refrigerant charge from system (WP 0222 00).

3.

Remove compressor from machine (WP 0221 00). Place protective caps on all fittings and hoses.

427-C2008

4.

Place compressor in a horizontal position so oil plug is facing downward. Remove oil plug from compressor. Drain oil

into a clean container. Rock compressor back and forth in order to remove all of oil. Also, rotate compressor shaft in

order to drain rest of oil that is in oil sump. Record volume of drained refrigerant. Inspect oil for the following items:

Metal chips

Rubber particles

Foreign material

5.

Dispose of oil in a suitable container. Use the following list as a guide for adding oil into compressor:

If amount of oil drained from compressor is 6 to 8 fl oz (177 to 237 ml), put same amount of

new refrigerant oil in compressor. Never refill with more than 8 fl oz (237 ml) of oil to com-

pressor unless system has been flushed.

If amount of oil is drained from compressor is less than 6 fl oz (177 ml), add 6 to 8 fl oz (177 to

237 ml) of new refrigerant oil to compressor.

If a new compressor or a rebuilt compressor is intalled, drain all oil from compressor and add

s

6 to 8 fl oz (177 to 237 ml) of new refrigerant oil in compressor.

If system was flushed, do not remove oil from a new compressor.

Refer to Table 2 if individual components are replaced withoutcharging compressor or without

flushing system.

0018 00-12