TM 5-3805-291-23-1

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

INCLUDING LUBRICATION INSTRUCTIONS - CONTINUED

0020 00

Table 1. Unit Preventive Maintenance Checks and Services (PMCS)

Including Lubrication Instructions for the 966H - Continued.

LOCATION

ITEM TO

CHECK/

ITEM

MAN-

NOT FULLY MISSION

NO.

INTERVAL HOURS

PROCEDURE

CAPABLE IF:

SERVICE

CAU T I ON

12

1,000 Hours

Rollover Pro-

or Semi-

tective Struc-

DO NOT straighten ROPS. Do not repair ROPS by welding rein-

annual

ture (ROPS)

forcement plates to ROPS. Any repair to ROPS will not return

ROPS to its original condition. A damaged ROPS must be

replaced.

a. Inspect ROPS for cracks, bends, or If cracks, bends, or broken welds

broken welds. Replace ROPS if are evident.

cracks, breaks, or bends are evident

(WP 0132 00).

CAU T I ON

ROPS mounting bolt threads should be coated with oil before

installing bolts. Failure to apply oil to bolt threads can result in

improper bolt torque.

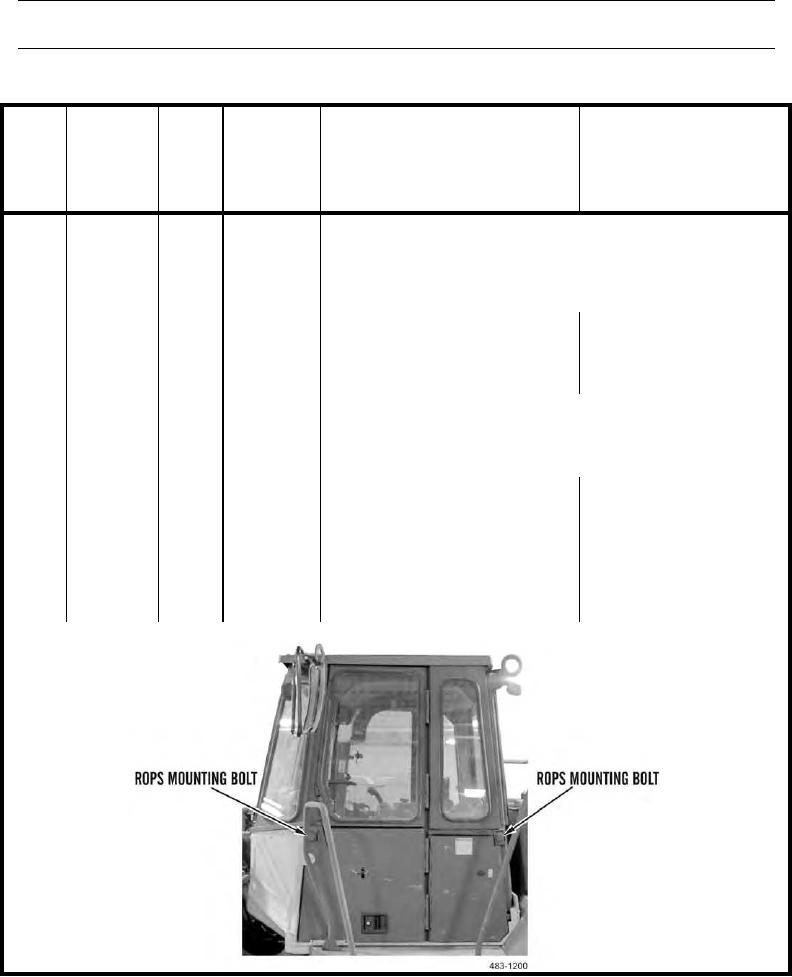

b. At each corner of cab, inspect ROPS

for loose or damaged mounting bolts

(TM 5-3805-291-10).

c. Replace any damaged or missing

bolts with original equipment parts

ONLY. Tighten bolts to 340 lb-ft (461

Nm).

0020 00-6