TM 5-3805-291-23-1

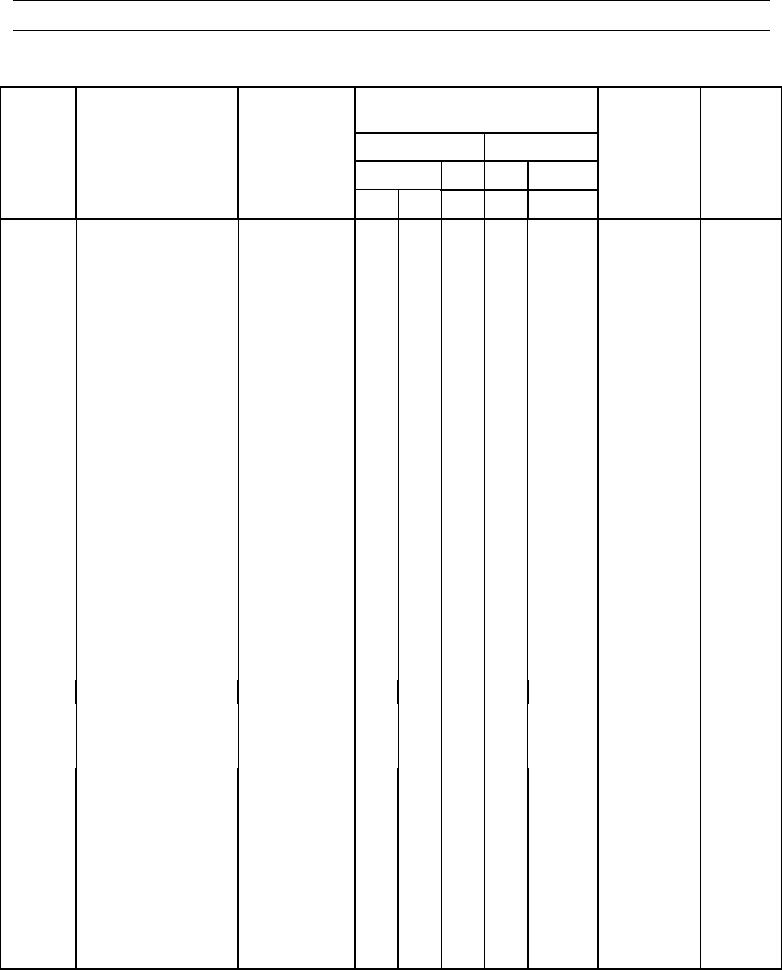

MAINTENANCE ALLOCATION CHART (MAC)

Table 1. Maintenance Allocation Chart (MAC) for 966H Loader.

(1)

(2)

(3)

(4)

(5)

(6)

MAINTENANCE LEVEL

FIELD

SUSTAINMENT

TOOLS AND

UNIT

DS

GS

DEPOT

GROUP

COMPONENT/

MAINTENANCE

EQUIPMENT REMARKS

C

O

F

H

D

NUMBER

ASSEMBLY

FUNCTION

REF CODE

CODE

01

ENGINE

Engine

Test

1.0

3,13,49,68,75,

E

84,86,87,89,90

0100

Engine Assembly

Inspect

0.3

B

Service

0.1

0.7

70,90

B

Replace

40.5

15,22,

A

41,68,90,99

Rebuild

60

D

0.3

Engine Mounts

Inspect

Replace

0.8

70,90

0101

Crankcase, Block, and

Cylinder Head

Cylinder Block

Inspect

0.7

D

Replace

20.0

D

Repair

8.0

D

Cylinder Head

Inspect

0.5

Assembly

Replace

22.5

68,90,98,99

A

Rebuild

8.0

D

0102

Crankshaft

Crankshaft

Inspect

0.5

D

Replace

14.5

D

Repair

1.5

D

Front Main Seal

Replace

10.5

68,90

Rear Main Seal

Replace

39.0

68,90

Vibration Damper and

Inspect

0.3

68,90

Pulley

Replace

9.0

68,90

0103

Flywheel

Flywheel

Inspect

38.0

25,26,

68,90

Replace

38.0

25,26,

68,90

Flywheel Housing

Inspect

42.0

25,26,68,90

Replace

42.0

25,26,68,90

0104

Piston, Connecting Rods Inspect

0.5

D

Replace

8.0

D