TM 5-3805-291-23-2

ENGINE WIRING HARNESS REPLACEMENT - CONTINUED

0196 00

REMOVAL - CONTINUED

427-C0331

INSTALLATION

1.

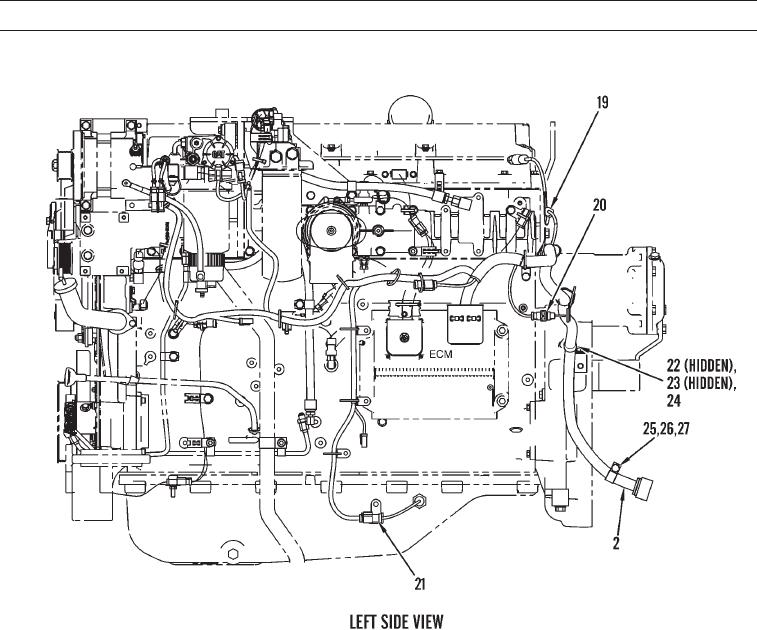

Position engine wiring harness (2) on machine.

2.

Connect engine wiring harness (2) to chassis wiring harness on left side of machine.

3.

Install washer (26), bolt (25), and clamp (27) on engine wiring harness (2) on left side of machine.

4.

Install washer (23), bolt (22), and clamp (24) on engine wiring harness (2) on right side of engine.

5.

Connect engine wiring harness (2) to service brake oil pressure sensor lead (21).

6.

Connect engine wiring harness (2) to torque converter oil pressure sensor (20).

7.

Connect engine wiring harness (2) to turbocharger inlet pressure sensor lead (19).

8.

Connect engine wiring harness (2) to AC compressor (18).

9.

Install two washers (16), bolts (15), and clamps (17) on machine.

0196 00-5