TM 5-3805-292-23

0052

CLEANING AND INSPECTION

00052

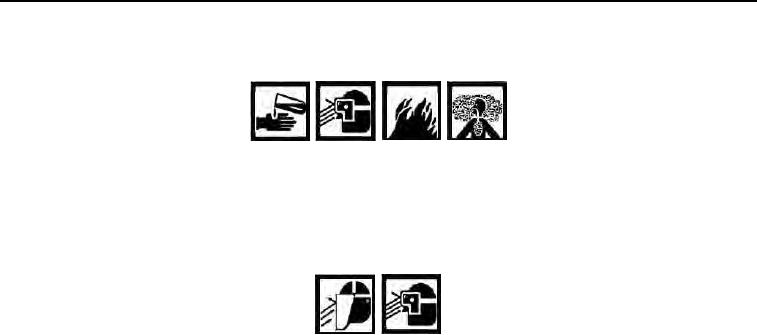

WARN I N G

Solvent cleaning compound MIL-PRF-680 Type III is an environmentally compliant and

low toxic material. However, it may be irritating to the eyes and skin. Use protective gloves

and goggles. Use in well-ventilated areas. Keep away from open flames and other

sources of ignition. Failure follow this warning may result in injury or death to personnel.

1. Clean all parts (except rubber and plastic surfaces) and mating surfaces with solvent cleaning compound.

WARN I N G

Particles blown by compressed air are hazardous. DO NOT exceed 15 psi (103 kPa)

nozzle pressure when drying parts with compressed air. DO NOT direct compressed air

against human skin. Make sure air stream is directed away from user and other personnel

in the area. To prevent injury, user must wear protective goggles or face shield. Failure to

follow this warning may result in injury to personnel.

2. Dry parts with compressed air.

3. Inspect parts for wear, pitting, cracks, or corrosion and replace if necessary.

END OF TASK

SERPENTINE BELT INSTALLATION/ADJUSTMENT

00052

N OT E

Fan is removed for viewing purposes only.

Install serpentine belt as noted during removal.

Skip to step 2 for serpentine belt adjustment

1. Install serpentine belt (Figure 1, Item 7) on machine.

2. Tighten two bolts (Figure 1, Items 1 and 2) on alternator (Figure 1, Item 8). Adjust belt tension by using deflec-

tion method. 1/4 inch at mid span between alternator and fan pulleys. Tighten jam nut.

END OF TASK

COMPRESSOR DRIVE BELT INSTALLATION/ADJUSTMENT

00052

N OT E

Fan is removed for viewing purposes only.

Install compressor drive belt as noted during removal.

Skip to step 2 for compressor drive belt adjustment.

1. Install compressor drive belt (Figure 1, Item 6) on machine.

2. Tighten two bolts (Figure 1, Items 3 and 4) on A/C compressor (Figure 1, Item 5). Adjust belt tension by using

deflection method. 1/4 inch at mid span between A/C compressor and fan pulleys. TIghten jam nut.

END OF TASK

0052-3