TM 55-607/NAVSEA OP 3221 Rev 2

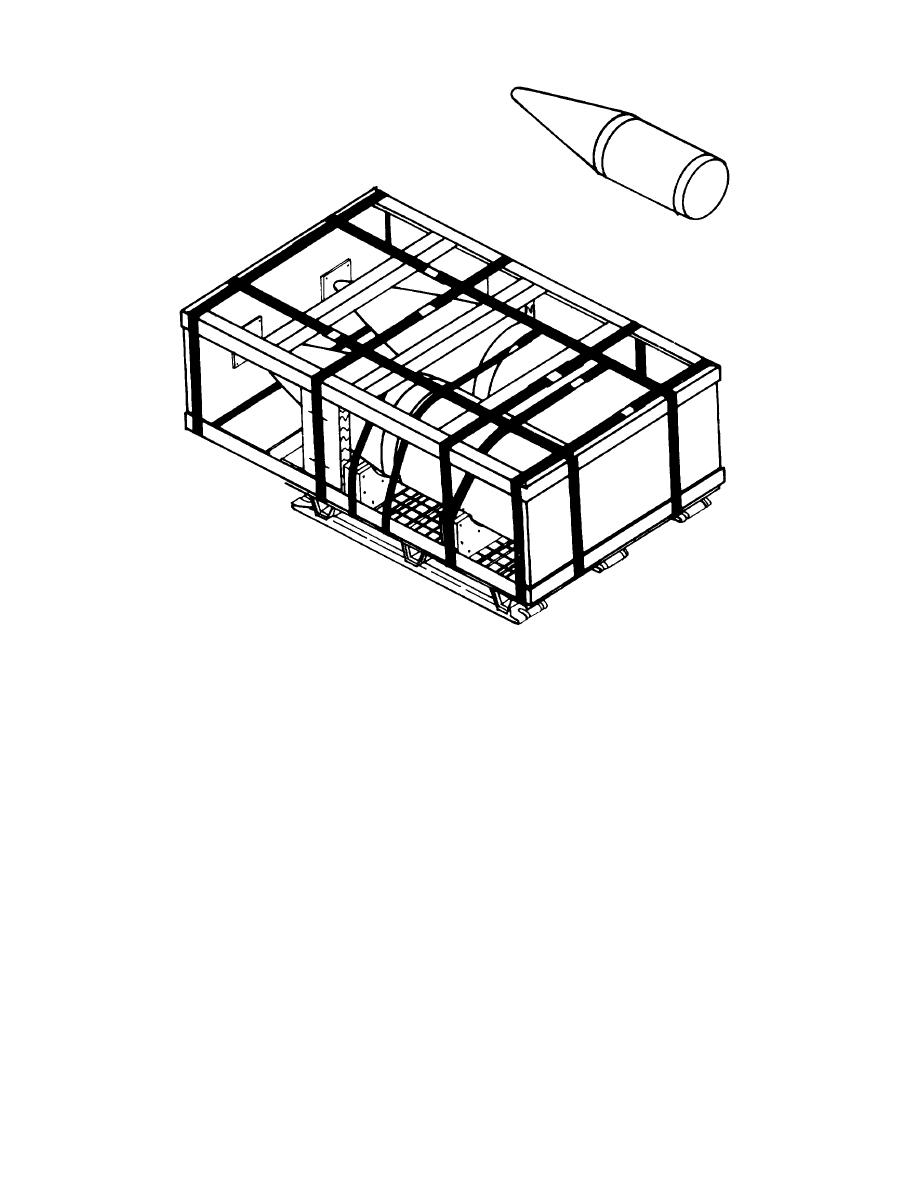

Figure 9-69. Two high-capacity (HC) projectiles (MK 3AMOI) 0 pallet).

(1) For block stowage of 16-inch HC projectiles, the unit loads can be stowed nose-to-nose, nose-to-base,

base-to-base, and nose/base-to-side. The top and bottom adapters and the plywood end cal)s provide an excellent

bearing surface between loads; thus, no additional dunnage is required. All unit loads, however, must retain the same

orientation when stacked vertically to assure that the on center pallets are vertically aligned for maximum stacking

stability. Because of their metal pallets, these unit loads require strip decking in any compartment that has a steel deck.

Care should be taken to assure that the strip decking supports all three pallet runners to prevent unit load distortion.

(2) For sweatboard-to-sweatboard stowage of HC projectiles, stowage patterns are more limited to prevent the

possibility of unstable stacks. The HC unit loads can be stowed nose-to-base, base-to-base, and nose/base-to-side.

Nose-to-nose stowage in the lower layers of a cargo stow is not considered acceptable, since it results in a long

unsupported section of' unit loads Upon which the pallet end of subsequent loads might be overstowed. In addition, when

subsequent tiers of projectile unit loads are offset by hull shear to such an extent that more than one-half of the pallet of

the overstowed load is not over any part of the palletized end of the lower load, 2by 8-inch minimum tier stripping should

be used to distribute the overstowed cargo weight. In cases where the pallets of overstowed unit loads are offset by less

than one-half, tier stripping is not required. As with the block stowage technique, strip decking is required to separate the

metal pallets from a ship's steel decks.

9-89