TM 55-607/NAVSEA OP 3221 Rev 2

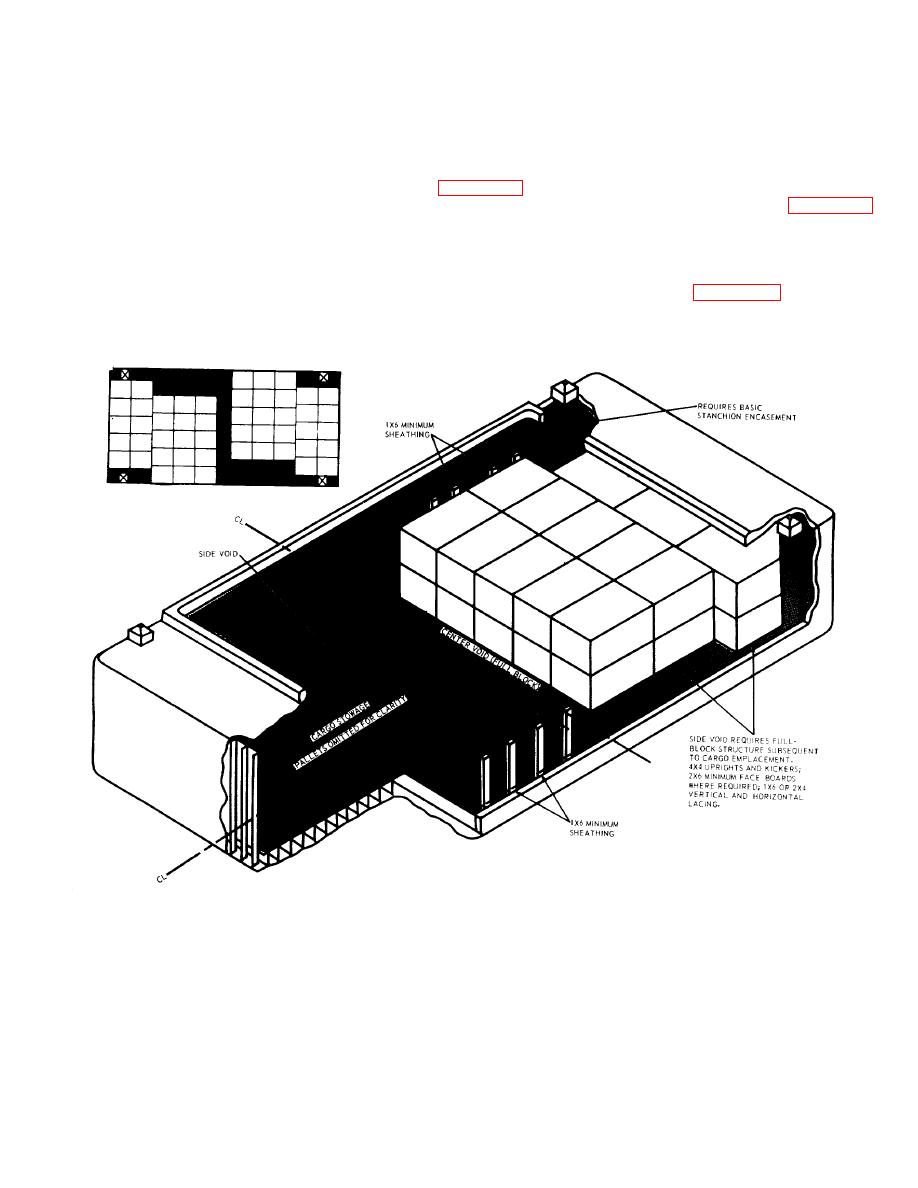

(2) Staggered block stow. This variation of the conventional block-stow pattern calls for cargo to be stowed

tightly against diagonally opposite side bulkheads of the lighter, starting at each end. Stowage proceeds in a tight pattern

across the lighter until the last load is fitted into place. The void that remains between the completed stow and the hull of

the lighter must be shored with a full-block structure similar to the one constructed on the longitudinal center line in the

conventional block-stow technique. Stowage progresses in this manner back toward the athwartship center line, where

any remaining voids are shored with full-block structures. Figure 10-6 illustrates the principles of the staggered block-

stow pattern. The loading of 1,000pound bombs (MK 83) by the staggered block-stow method is shown in figure 10-7.

By offsetting the loads in opposite directions around the longitudinal center line, the lighter remains balanced. Staggered

block-stow permits efficient forklift truck operation in the square of the hatch, since stowage operations take place in

opposite corners of the lighter. Sheathing and encasement structures are required only on one side and at the ends of

the barge. Also, the smooth steel construction of the lighter's side bulkhead facilitates installation of the full-block

structure, especially if the cargo stow consists of mixed commodities of varying dimensions. Figure 10-8 illustrates a

typical void shoring structure installed at the hull when the staggered block-stowage technique is used.

Figure 10-6. Basic staggered block-stow pattern.

10-8